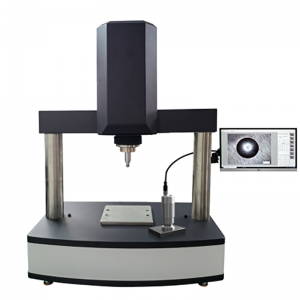

ZHB-3000A Fully automatic Brinell Hardness Tester

Hardness is one of the important indices of material mechanical performance. And hardness test is the important means to determine metal material or the quality of product parts. Because of the corresponding relation between metal hardness and other mechanical performance, therefore, most metal materials can be measured the hardness to approximately calculate the other mechanical performance, such as strength, fatigue, creep and wear. Brinell hardness test can satisfy the determination of all the metal material hardness by using different test forces or changing different ball indenters.

The instrument adopts integrated design of hardness tester and panel computer. With the Win7 operating system, it has all the functions of the computer.

With CCD image acquisition system, it directly shows the indentation image and automatically gets the Brinell hardness value. It takes over the old method of measuring the diagonal length by eyepiece, avoids the stimulation and visual fatigue of the light source of the eyepiece, and protects the eyesight of the operator. It is a major innovation of Brinell hardness tester.

The instrument can apply to the measurement of cast iron, nonferrous metal and alloy material, various annealing, hardening and tempering steel, especially the soft metal such as aluminum, lead, tin etc. which makes the hardness value more correct.

Suitable for cast iron, steel products, nonferrous metals and soft alloys etc. Also suitable for some nonmetal materials such as rigid plastics and bakelite etc.

• It adopts integrated design of hardness tester and panel computer. All the testing parameters can be selected on the panel computer.

• With CCD image acquisition system, you can get the hardness value just by touching the screen.

• This instrument has 10 level of test force, 13 Brinell hardness test scales, free to choose.

• With three indenters and two objectives, automatic recognition and shifting between the objective and the indenter.

• The lifting screw realizes the automatic lifting.

• With the function of hardness conversion between each scale of hardness values.

• The system has two languages: English and Chinese.

• It can automatically save the measuring data, save as WORD or EXCEL document.

• With several USB and RS232 interfaces, the hardness measurement can be print out by USB interface (equipped with an external printer).

• With optional automatic lifting test table.

Test Force:

62.5kgf, 100kgf, 125kgf, 187.5kgf, 250kgf, 500kgf, 750kgf, 1000kgf, 1500kgf, 3000kgf (kgf)

612.9N, 980.7N, 1226N, 1839N, 2452N, 4903N, 7355N, 9807N, 14710N, 29420N (N)

Test Range: 3.18~653HBW

Loading Method: Automatic (Loading/Dwell/Unloading)

Hardness Reading: Indentation Displaying and Automatic Measuring on Touch Screen

Computer: CPU: Intel I5,Memory: 2G,SSD: 64G

CCD Pixel: 3.00 Million

Conversion Scale: HV, HK, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HS, HBS, HBW

Data Output: USB Port, VGA Interface, Network Interface

Shifting between Objective and Indenter: Automatic Recognition and Shifting

Objective and Indenter: Three Indenters, Two Objectives

Objective: 1× ,2×

Resolution: 3μm ,1.5μm

Dwell Time: 0~95s

Max. Height of Specimen: 260mm

Throat: 150mm

Power Supply: AC220V, 50Hz

Executive Standard: ISO 6506,ASTM E10-12,JIS Z2243,GB/T 231.2

Dimension: 700×380×1000mm,Packing Dimension: 920×510×1280mm

Weight: Net Weight: 200kg,Gross Weight: 230kg

|

Item |

Description |

Specification |

Quantity |

|

|

No. |

Name |

|||

|

Main Instrument |

1 |

Hardness tester |

1 piece |

|

|

2 |

Ball indenter | φ10、φ5、φ2.5 |

Total 3 pieces |

|

|

3 |

Objective | 1╳、2╳ |

Total 2 pieces |

|

|

4 |

Panel computer |

1 piece |

||

|

Accessories |

5 |

Accessory box |

1 piece |

|

|

6 |

V-shaped test table |

1 piece |

||

|

7 |

Large plane test table |

1 piece |

||

|

8 |

Small plane test table |

1 piece |

||

|

9 |

Dust-proof plastic bag |

1 piece |

||

|

10 |

Inner hexagon spanner3mm |

1 piece |

||

|

11 |

Power cord |

1 piece |

||

|

12 |

Spare fuse | 2A |

2 pieces |

|

|

13 |

Brinell hardness test block (150~250)HBW3000/10 |

1 piece |

||

|

14 |

Brinell hardness test block (150~250)HBW750/5 |

1 piece |

||

|

Documents |

15 |

Usage instruction manual |

1 piece |

|