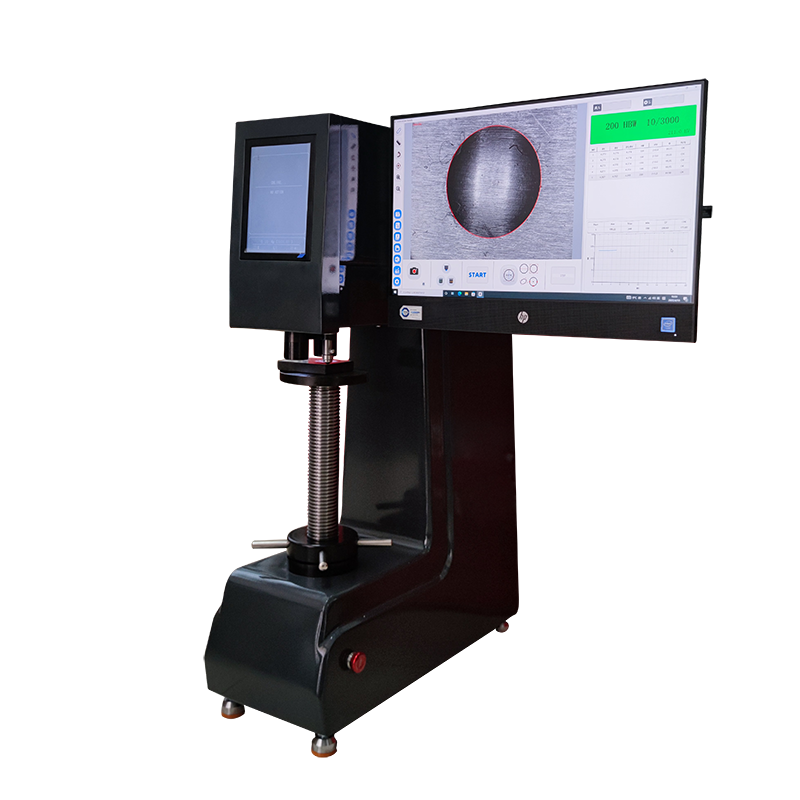

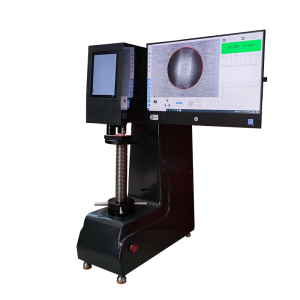

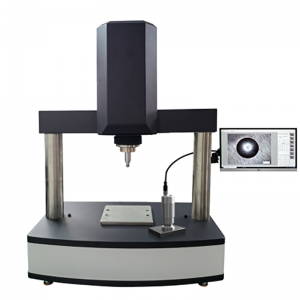

ZHB-3000 Semi-automatic Brinell Hardness Tester

* Brinell hardness tester adopts 8-inch touch screen and high-speed ARM processor, which is intuitive, user-friendly and easy to operate, featuring fast operation, large database storage, automatic data correction, and data break report.;

* An industrial panel PC mounted on the side of the body with a built-in industrial grade camera. Processing is performed using CCD image software. Data and images can be output directly.

* The body of the machine is made of high-quality cast iron in one go, with the processing technology of auto baking paint.;

* Equipped with automatic turret, automatic switching between pressure head and target, easy to use;

* Maximum and minimum hardness values can be set. Alarm will sound when the test value exceeds the set range;

* The software's hardness value correction function allows direct modification of hardness values within a certain range.;

* The test data can be automatically grouped and saved by the function of database. Each group can save 10 data, over 2000 data.;

* With hardness value curve display function, the instrument can visually display the change of hardness value.

* Full hardness scale conversion;

* Closed-loop control, automatic loading, dwell and unloading;

* Equipped with high definition dual targets; can measure indentations of different diameters at test forces from 31.25-3000kgf.;

* Equipped with wireless Bluetooth printer, data can be output via RS232 or USB;

* Accuracy conforms to GB/T 231.2, ISO 6506-2 and ASTM E10 standards.

It is suitable for determining the Brinell hardness of unhardened steel, cast iron, non-ferrous metals and soft bearing alloys. It is also suitable for hardness testing of hard plastics, Bakelite and other non-metallic materials. It has a wide range of applications and is suitable for precision measurement of flat surfaces with stable and reliable surface measurements.

Measuring range: 8-650HBW

Test force: 306.25, 612.9, 980.7, 1226, 1839, 2452, 4903, 7355, 9807, 14710, 29420N(31.25, 62.5, 100, 125, 187.5, 250, 500, 750, 1000, 1500, 3000kgf)

Max. height of test piece: 280mm

Depth of throat: 165mm

Hardness Reading: LCD digital display

Objective: 10X 20x

Min measuring unit : 5μm

Diameter of tungsten carbide ball: 2.5, 5, 10mm

Dwelling time of test force:1~99S

CCD: 5 mega-pixel

CCD measuring method: Manual/Automatic

Power supply: 220V AC 50HZ

Dimensions: 700*268*980mm

Weight Approx. 210kg

| Main unit 1 | Brinell standardized block 2 |

| Large flat anvil 1 | Power cable 1 |

| V-notch anvil 1 | Anti-dust cover 1 |

| Tungsten carbide ball indenterΦ2.5, Φ5, Φ10mm, 1 pc. each | Spanner 1 |

| PC/Computer: 1pc | User manual: 1 |

| CCD measuring system 1 | Certificate 1 |