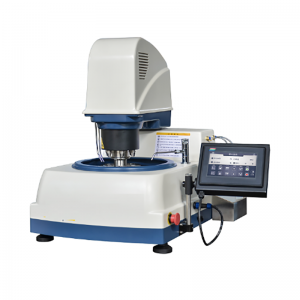

YMPZ-1A-300/250 Automatic metallographic sample grinding polishing machine with automatic suspension dropping device

1.Two operating modes: central pressure and single point pressure, the most suitable method can be selected according to the working conditions

2.The sample chuck can be quickly loaded and unloaded, and the chuck of different calibers can be used flexibly

3. Magnetic disc design, support quick disc change, backing plate sprayed with Teflon, no residue after changing sandpaper and polishing cloth

4.The unique self-adaptive design of the grinding disc makes the sample and the grinding disc perfectly fit and correct, effectively solve the multi-faceted phenomenon, and ensure the consistency of the grinding surface

5.The whole machine adopts high-definition LCD touch screen control and display, easy to operate, clear and intuitive

6.Automatic grinding system, timing and speed, automatic opening and closing function of water system, effectively replacing manual grinding and polishing

7.Automatic lock-off function of the electromagnetic lock of the grinding head, safe and convenient

8.Brushless DC motor, long service life, ultra-quiet experience

9.Can store 10 kinds of grinding and polishing programs, and different parameters can be set for different samples

10.The sample chuck half-turn design, with the internal lighting system, convenient to take and place the sample

Various metallographic samples

Light labor demand

In the metallographic sample preparation, pre-grinding, polishing and grinding are the indispensable procedures. The suspension needs to drop in the process of grinding and polishing, so this dropping device is just designed for the automatic dropping of the suspension. This machine is controlled by single chip microcomputer, and it is output by a precise peristaltic pump. The touch panel displays and controls the input speed. The motor is the 24V DC brush motor, used for a long time, and can completely replace the artificial drops. It has reached the purpose of timing and uniform output of the suspension. The machine can adapt to the output of various suspensions and can be used for various grinding and polishing machines. Its easy operation, compact appearance and safety make it the best ancillary equipment for metallographic sample preparation.

|

Storage Bottle Volume |

500ml |

|

Time setting range |

0-9999s (Drop once every X seconds) |

|

Motor |

24V DC brush motor, 9W |

|

Dimensions |

100×203×245mm |

|

Weight |

4kg |

|

model |

YMPZ-1A-300 |

YMPZ-1A-250 |

|

Diameter of grinding polishing disc |

300mm |

254mm |

|

Sandpaper diameter |

300mm |

250mm |

|

Rotating Speed of Grinding Disc |

Stepless speed regulation 100~1000r/min |

|

|

Disc Rotational Direction |

Clockwise or counterclockwise |

|

|

Disc Electromotor |

Brushless DC motor, 220V, 1.2kW |

|

|

Head Electromotor |

Stepper motor, 200W |

|

|

Rotating speed of grinding head |

Stepless speed 20~120r/min |

|

|

Timing adjustable time |

0~99min |

|

|

Number of specimen holding |

6pcs |

|

|

Specimen holder specifications |

Φ25mm, Φ30mm, Φ40mm(choose one), (Special specifications can be customized) |

|

|

Pressure method |

Single point pneumatic pressure and center pneumatic pressure |

|

|

Single point pressure |

0~50N |

|

|

Central pressure |

0~160N |

|

|

Display and operation |

7-inch high-definition LCD touch screen, automatic locking function of the grinding head, automatic water outlet function,suspension is automatically titrated |

|

| Drip bottle capacity |

500mm/bottle, 2bottles |

|

|

Input power |

Single-phase 220V, 50Hz, 8A |

|

|

Dimensions |

800×800×760mm |

|

|

Net weight |

100kg |

|

| name | Specification | quantity |

| Main machine body | 1 set | |

| Automatic grinding head | 1 pc | |

| Specimen holder | 2 pcs | |

| Sample leveling plate | 1 pc | |

| Grinding and polishing disc | 300/254mm | 1 pc |

| Magnetic disk | 300/250mm | 1 |

| Metal disc | 300/250mm | 4pcs |

| Adhesive sandpaper | 300/250mm | 6 pcs |

| Adhesive polishing cloth | 300/250mm | 2pcs |

| Inlet pipe | Washing machine water inlet pipe | 1pc |

| Outlet pipe | Φ32mm | 1pc |

| Water inlet filter | 1pc | |

| Air pipe | 1pc | |

| Grinding head connection cable | 2 pcs | |

| Allen wrench | 3mm, 5mm, 6mm | Each 1pc |

| Automatic dropping device | 1set | |

| Drip bottle | 500ml | 2pcs |

| manual | 1copy | |

| Certificate of conformity | 1 copy |

| name | Specification |

| Adhesive sandpaper 300 (250) mm | 180#,240#,280#,320#,400#,600#,800#,

1000#,1200#,1500#,2000# |

| Adhesive polishing cloth 300 (250) mm | Canvas, velvet, woolen cloth, long velvet |

| Diamond paste | W0.5, W1, W2.5, W3.5, W5 |

| Diamond spray | W0.5, W1, W2.5, W3.5, W5 |

| Diamond suspension | W1, W2.5, W3.5, W5 |

| Alumina final polishing liquid | W0.03, W0.05 |

| Silica final polishing liquid | W0.03, W0.05 |

| Alumina | W1, W3, W5 |

| Chromium oxide | W1, W3, W5 |