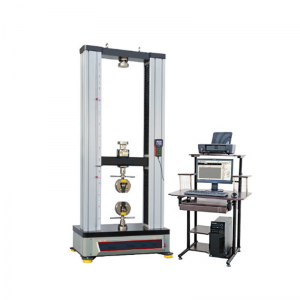

WDW-100 Computer Control Electronic Universal Testing Machine

This machine is an important instrument and equipment for testing the physical properties, mechanical properties, technological properties, structural properties and internal and external defects of various materials and their products. After matching the corresponding fixture, the tensile, compression, bending, shearing, peeling and other types of tests on metal or non-metallic materials can be completed; high-precision load cells and high-resolution displacement sensors are used to ensure accurate measurement; Closed-loop control of load, constant rate deformation, and constant rate displacement.

This machine is easy to install, simple to operate, and efficient to test; it is widely used in universities, scientific research institutes, testing institutions, aerospace, military, metallurgy, machinery manufacturing, transportation construction, construction materials and other industries for precise material research and material analysis , material development and quality control; can carry out the process qualification performance verification test of materials or products.

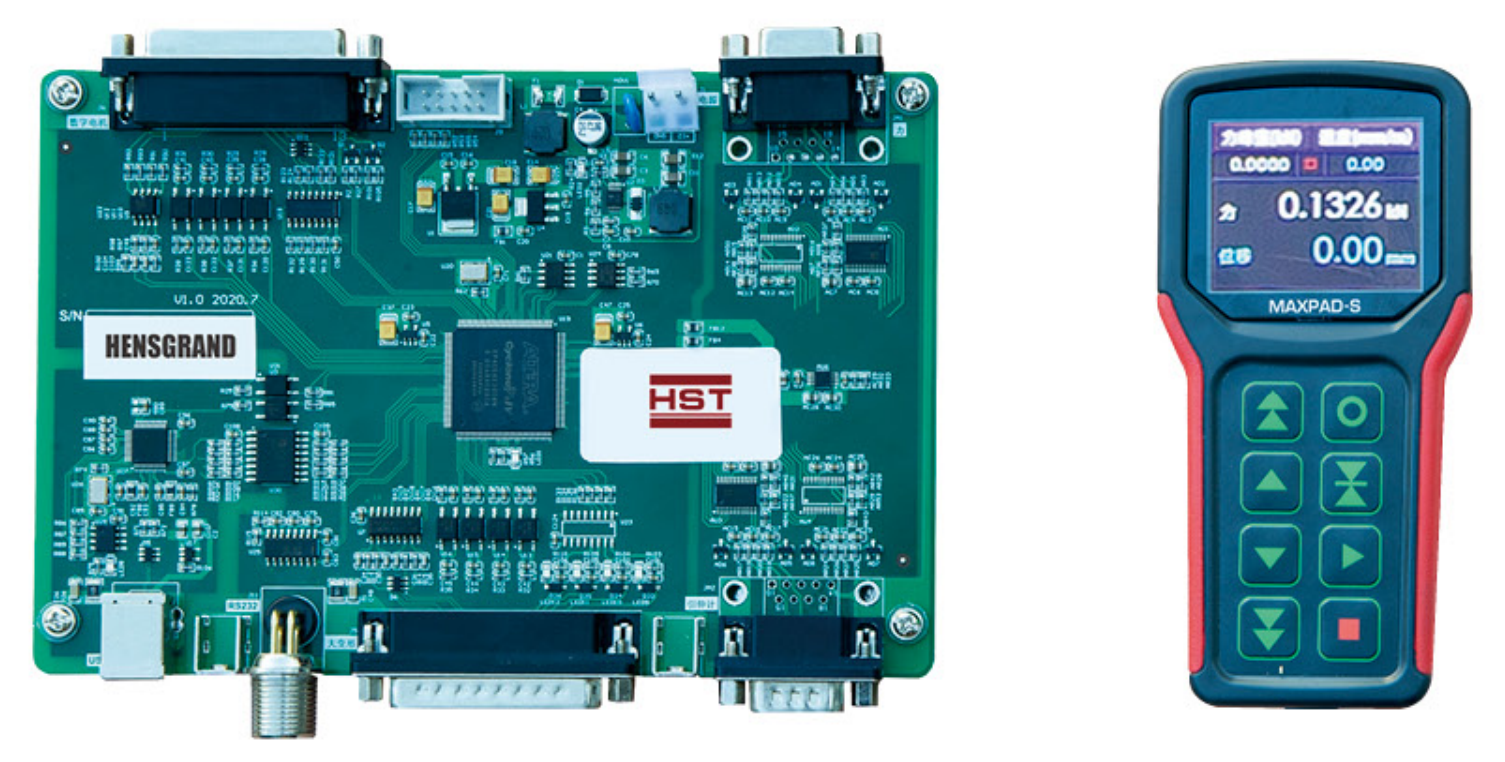

External independent controller

External independent controller a new generation of static testing machine special controller, is a set of measurement, control, transmission functions in one, and the signal acquisition, signal amplification, data transmission, servo motor drive unit is highly integrated; For testing machine measurement, control and operation to provide a new solution, USB data transmission fully support notebook computers, tablet computers, desktop computers; Is an important part of the development of testing machine technology.

The external handheld controller uses 320*240 LED display, which can quickly adjust the test space, and has the function of test start, test stop, test clearing, etc., real-time display of equipment running status, test data, so that the sample clamping is more convenient, more

simple operation.

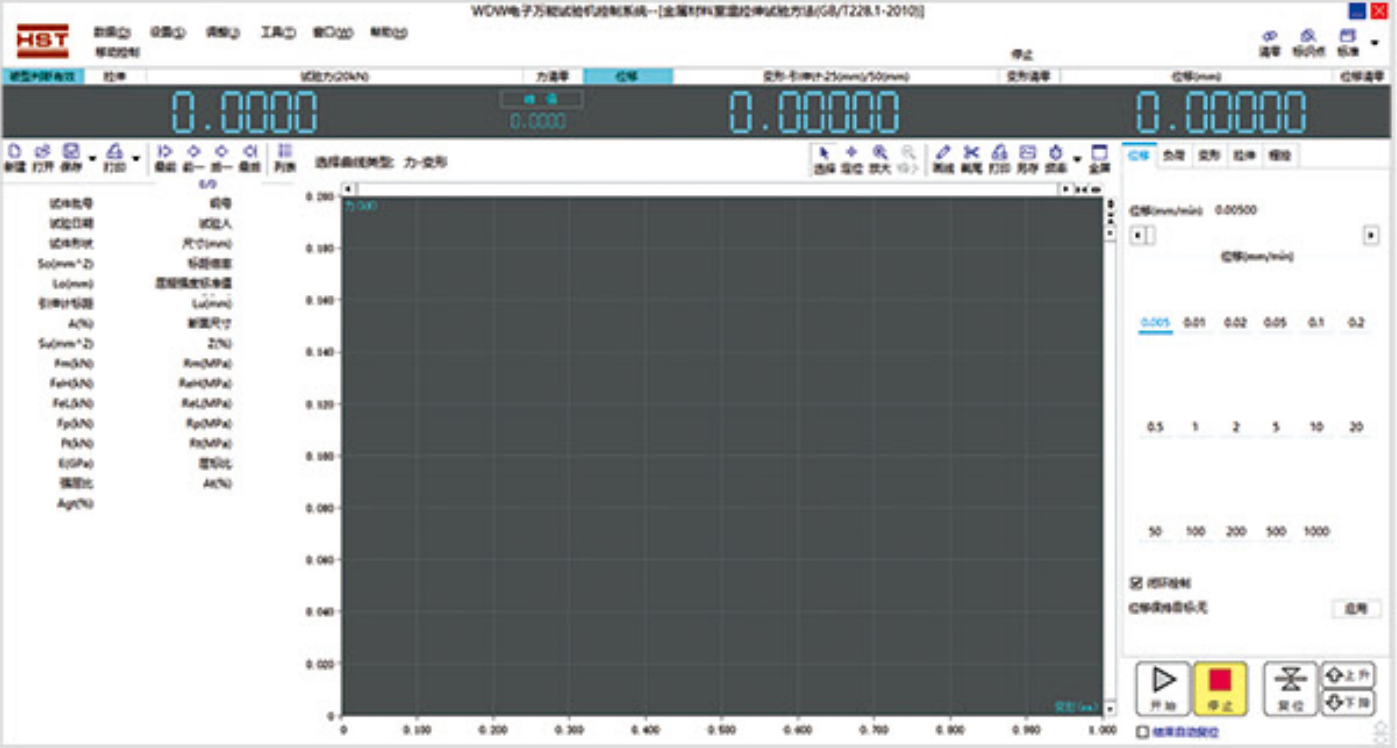

Universal testing machine measurement and control software

The measurement and control software of the universal testing machine adopts DSP technology and neuron adaptive control algorithm to realize various closed-loop control modes such as constant rate test force, constant rate beam displacement, constant rate strain, etc. The control methods can be arbitrarily combined and smoothly switched. Realize data networking and remote control functions.

Measurement Parameter

Maximum testing machine (kN): 100;

Testing machine level: 0.5;

Effective measurement range of test force: 0.4%-100%F.S;

Test force measurement accuracy: better than ≤±0.5%;

Displacement measurement resolution: 0.2μm;

Displacement measurement accuracy: better than ≤±0.5%;

Measuring range of electronic extensometer: 0.4%-100%FS;

Electronic extensometer measurement accuracy: better than ≤±0.5%;

Control parameter

Force control speed range: 0.001%~5%FS/s;

Force control speed control accuracy: 0.001%~1%FS/s is better than ≤±0.5%;

1%~5%FS/s is better than ≤±0.2%;

Force control retention accuracy: ≤±0.1%F.S;

Deformation control control speed range: 0.001%~5%FS/s;

Deformation control speed control accuracy: 0.001%~1%FS/s is better than ±0.5%;

1%~5%FS/s is better than ±0.2%;

Deformation control and retention accuracy: ≤±0.02%F.S;

Displacement control speed range: 0.01~500mm/min;

Displacement control and speed control accuracy: ≤±0.2%;

Displacement control retention accuracy: ≤±0.02mm;

Control mode: force closed-loop control, deformation closed-loop control, displacement closed-loop control;

3.3 Machine parameters

Number of columns: 6 columns (4 columns, 2 lead screws);

Maximum compression space (mm): 1000;

Maximum stretching distance (mm): 650 (including wedge-shaped stretching fixture);

Effective span (mm): 550;

Worktable size (mm): 800×425;

Mainframe dimensions (mm): 950*660*2000;

Weight (kg): 680;

Power, voltage, frequency: 1kW/220V/50~60Hz;

Main Machine

| Item | QTY | Remark |

| Working table | 1 | 45# steel, CNC precision machining |

| Double convex cross head moving beam |

1 | 45# steel, CNC precision machining |

| upper beam | 1 | 45# steel, CNC precision machining |

| Host backplane | 1 | Q235-A,CNC precision machining |

| Ball screw | 2 | Bearing steel, precision extruded |

| support column | 4 | Precision extrusion, high frequency surface, electroplating, polishing |

| AC Servo Motor, AC Servo Drive | 1 | TECO |

| Planetary gear reducer | 1 | shimpo |

| Timing belt / Timing pulley | 1 | Sables |

Measurement and control, electrical part

|

Item |

QTY |

Remark |

|

Exteral measurement & control |

1 |

Multi-channel, high precision |

|

Electric Universal Testing Machine measurement control software |

1 |

Inside more than 200 testing standard |

|

External handheld control box |

1 |

Test force, displacement, speed display |

|

The device runs the drag system |

1 |

With overcurrent and other protection functions |

|

High-precision spoke-type load cell |

1 |

chcontech”100KN |

|

High Precision Displacement Sensor |

1 |

TECO |

|

Extensometer |

1 |

50/10mm |

|

computer |

1 |

HP desktop |

Accessories

| Item | QTY | Remark |

| Dedicated wedge-shaped tensile jig | 1 | Rotary clamping type |

| round sample block | 1 | Φ4~φ9mm,hardness HRC58~HRC62 |

| Flat sample block | 1 | 0~7mm, hardness HRC58~HRC62 |

| Dedicated compression attachment | 1 | Φ90mm,quenching treatment 52-55HRC |

Documentation

| Item | QTY |

| Operation instructions for mechanical parts | 1 |

| Software Instruction Manual | 1 |

| Packing list/certificate of conformity | 1 |