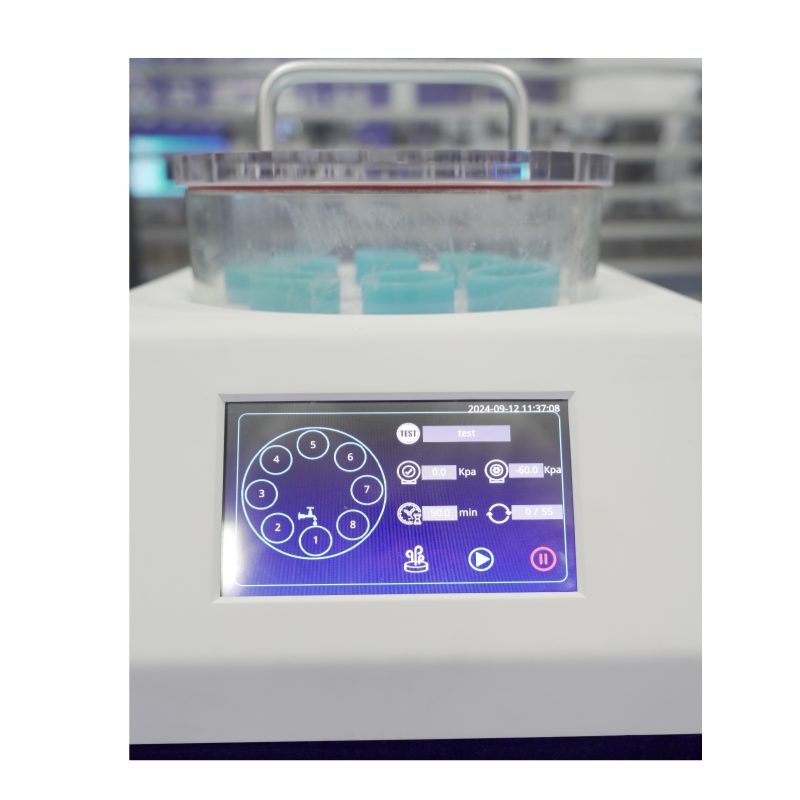

SXQ-2 Vacuum Inlaying Machine

Inlay is a very important step in the preparation of metallographic samples, especially for some samples that are not easy to handle, small samples, samples with irregular shape that need to protect the edge or samples that need to be automatically polished, inlay of samples is an essential process.

SXQ-2 vacuum inlaying machine has compact design, large capacity, simple and fast operation, and high equipment reliability. The built-in vacuum pump can quickly and effectively vacuum, suitable for vacuum cold inlaying of epoxy resin, can effectively remove the bubbles in the sample and resin, so that the resin penetrates into the pores and cracks of the sample, obtain the sample without bubbles and pores, and improve the final Mosaic effect of the sample.It is very suitable for the preparation of porous materials, such as failure analysis samples for cracks, porous castings and composite materials, electronic components, rock minerals, ceramics and other samples

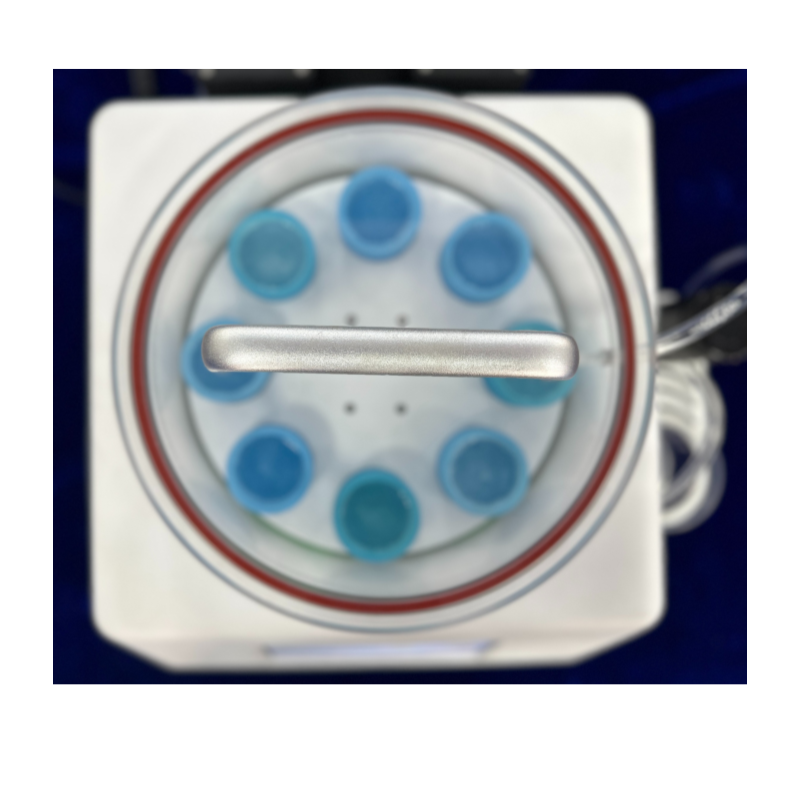

◆Built-in low noise vacuum pump for up to 8 samples (Φ40mm diameter).

◆Electric vacuum speed, high vacuum.

◆Full transparent large vacuum chamber, the most rotating table, manual knob pouring, convenient and fast.

◆Program control, can set the vacuum degree, the number of cycles and the corresponding time, automatically complete the whole inlaying process such as multiple samples, multiple vacuuming, maintaining vacuum, and venting cycle.

|

Name |

SXQ-2 |

|

Vacuum degree |

0~-75kPa, Vacuum pump 0~-90kPa |

|

Factory default vacuum |

-70 kPa |

|

Vacuum flow |

10~20L/min |

|

Vacuum chamber Size |

Φ250mm×120mm

up to 8 samples (Φ40mm diameter) |

|

Work panel control |

Touch screen control, click the corresponding electric rotary table to rotate |

|

Operation |

7 inch touch screen, manual knob casting |

|

Timing cycle |

0~99min, Auto pumping/deflating, auto circulation |

|

Maximum cycle number |

99 times |

|

Power supply |

Single-phase 220V, 50Hz, 10A |

|

Dimension |

400*440*280mm |

|

Weight |

24kg |

|

Name |

Specification |

Qty |

|

Main Machine |

SXQ-2 |

1 set |

|

Cold molding |

40mm |

8 pcs |

|

Disposable pouring pipe |

|

5 pcs |

|

Disposable paper cups |

|

5 pcs |

|

Stir stick |

|

5 pcs |

|

Manual |

|

1 copy |

|

Certificate |

|

1 copy |