SCR3.0 Fully Automatic Rockwell & Superficial Rockwell Hardness Tester with auto XY workbench

Rockwell hardness test method, can use diamond indenter and steel ball indenter, can measure harder and softer samples, widely used to determine the Rockwell hardness of ferrous metals, non-ferrous metals, non-metallic materials.

It is mainly used to measure Rockwell hardness of heat treated materials such as quenching and tempering. Such as carbide, carburized steel, hardened steel, surface hardened steel, hard cast steel, aluminum alloy, copper alloy, malleable casting, mild steel, tempered steel, annealed steel, bearings and other materials.

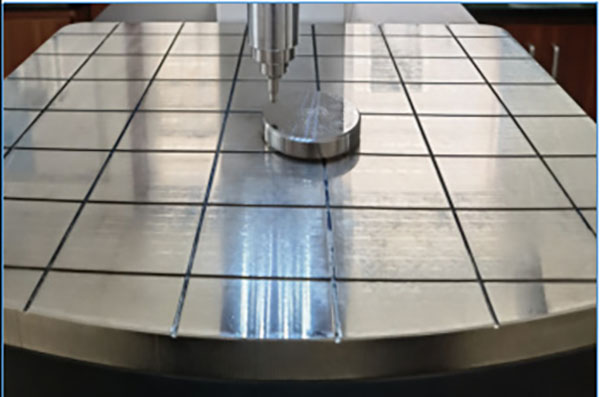

Large test workbench provides a large test space for testing products, but also according to customer needs, commissions professional customized solutions.

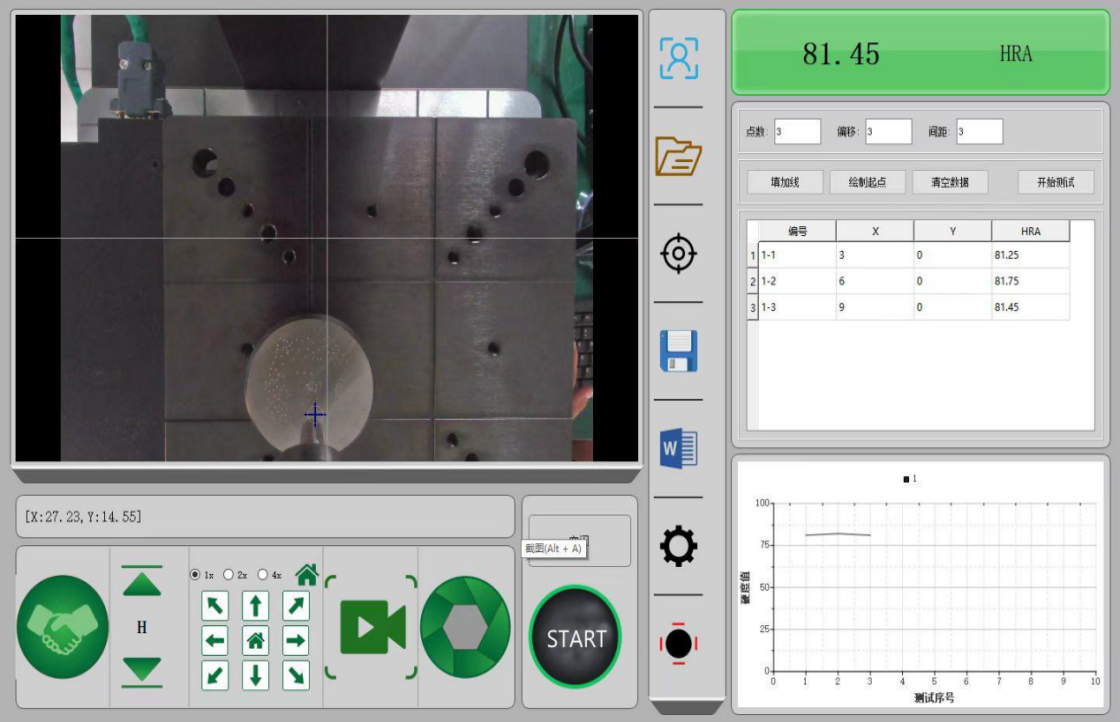

Large test workbench provides a large test space for testing, but also according to customer needs, commissions professional customized solutions. High precision grating ruler is used to control the displacement of the fully automatic XY stage. Also can be customized according to the user's special sample fixture location requirements.

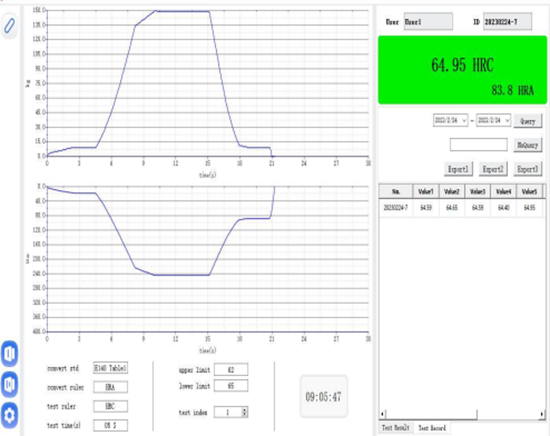

Electronic loading test force is used to replace the weight force, which improves the accuracy of the force value and makes the measured value more

stable. 8” Touch Screen, easy operation

Integrated test space lighting system highlights the measurement site to ensure clarity & visibility, ensuring accurate positioning of indenter. Bluetooth connect with computer, through special hardness software analysis, management data;

Configurable protocols and data output can be matched with automated production lines to achieve online detection.

Can convert HB, HV and other hardness system, set the maximum value, minimum value, average value and so on;

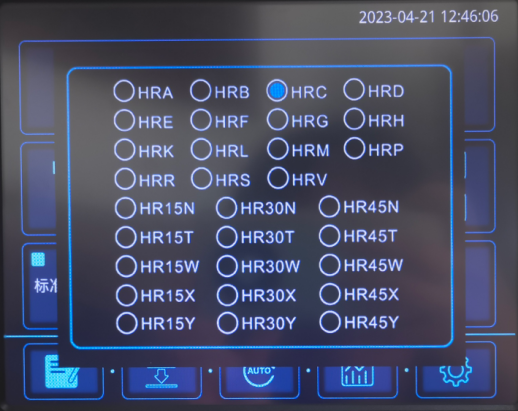

Powerful data processing function, test Rockwell 15 kinds of hardness and superficial Rockwell scale;

Operation interface is simple & humanized, hardness scale is selected by touch screen operation;

Initial load holding time and loading time can be set freely, with hardness correction function

ISO, GBT,ASTM standard

Optionally equipped with a panoramic camera, the test path can be set directly on the image for multi-line and multi-point continuous testing.

The test path can be saved as a template for easy invocation at any time. Suitable for automatic inspection of batch parts.

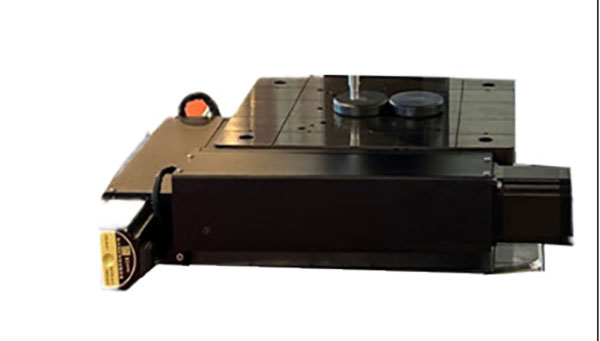

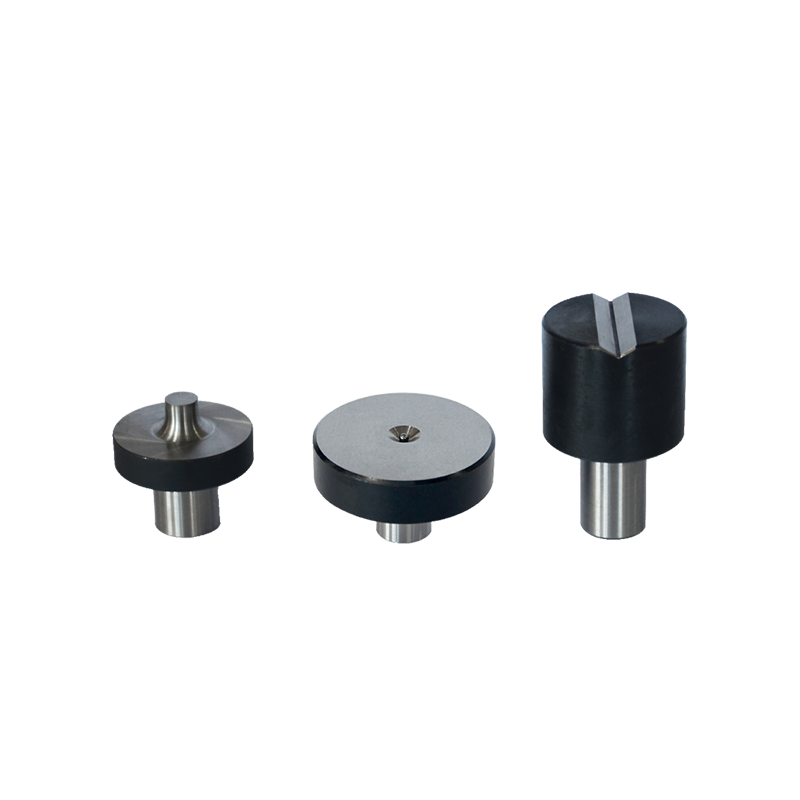

Single-axis electric displacement table (optional)

The precise guide column effectively ensures the accuracy and straightness of the movement

| Test force | Rockwell:60kg,100kg,150kg | |

| Superficial Rockwell:15kg,30kg,45kg | ||

| Resolution | ±1% | |

| Measuring Range | Rockwell:20-88HRA,20-100HRB,20-70HRCSuperficia:70-91HR15N,42-80HR30N,20-70HR45N,73-93HR15T,43-82HR30T,12-72HR45T | |

| Indenter type | Rockwell Diamond indenter | ф1.588mm Ball indenter |

| Measuring space | Max test height:200mm | |

| Throat: 200mm | ||

| Dwell time | Intinial test force: 0.1-50sec Total test force: 0.1-50sec | |

| Operation | Machine head indenter auto up and down, one button operation

|

|

| Display | 8” touch screen,Hardness value display, parameter setting, data statistics, storage, etc

|

|

| Indication resolution | 0.01HR | |

| Measuring scale | HRA,HRD,HRC,HRF,HRB,HRG,HRH,HRE,HRK,HRL,HRM,HRP,HRR,HRS,HRV, HR15N,HR30N,HR45N,HR15T,HR30T,HR45T,HR15W,HR30W,HR45W,HR15X, HR30X,HR45X,HR15Y,HR30Y,HR45Y | |

| Conversation Scale | ISO6508,ASTME18,JISZ2245,GB/T230.2 | |

| Data statistics | Test times, average value, maximum value, minimum value, repeatability, setting upper and lower limits of hardness value, warning function, etc | |

| Data output | USB,RS232 | |

| Power Supply | AC220V,50Hz | |

End quenching table (optional)

Other working table

| Name | Qty | Name | Qty |

| Main Machine | 1set | Diamond Indenter | 1pc |

| Φ1.588mm Ball indenter | 1pc | XY auto workbench | 1set |

| Rockwell hardness block 20-30HRC | 1pc | Rockwell hardness block 60-62HRC | 1pc |

| Superficial Rockwell hardness block 65-80HR30N | 1pc | Superficial Rockwell hardness block 70-85HR30TW | 1pc |

| Superficial Rockwell hardness block 80-90HR15N | 1pc | Power cable | 1pc |

| Dust cover | 1pc | Document | 1share |