SCR2.0 Fully Automatic Rockwell hardness tester

1.The electronic loading test force replaces the weight force, which improves the accuracy of the force value and makes the measured value more stable.

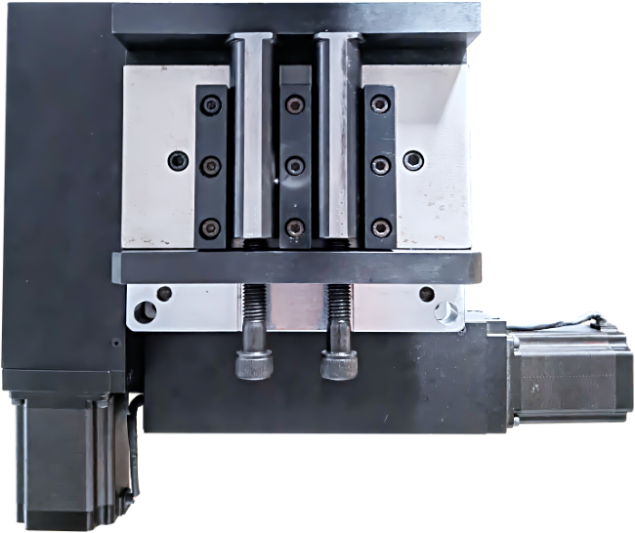

2.High precision grating ruler is used to control the displacement of the fully automatic XY stage. It can also be customized according to the user's special sample fixture location requirements.

3.Configurable protocols and data output can be matched with automated production lines to achieve online detection.

4.Eight-inch touch screen operation and display, humanized operation interface, complete instrument Settings;

5.RS-232 interface or Bluetooth connection computer, through the special hardness software analysis, management data;

6.Can convert HB, HV and other hardness system, set the maximum value, minimum value, average value and so on;

7.Powerful data processing function, test Rockwell 15 kinds of hardness and surface Rockwell scale optional;

8.The operation interface is simple, humanized interface sets parameters, and the required hardness scale is selected by touch screen operation;

9.Initial load holding time and loading time can be set freely, with hardness correction function

10.Hardness values can be converted according to ISO, ASTM, GB and other standards.

Rockwell hardness test method, can use diamond indenter and steel ball indenter, can measure harder and softer samples, widely used to determine the Rockwell hardness of ferrous metals, non-ferrous metals, non-metallic materials.

It is mainly used to measure Rockwell hardness of heat treated materials such as quenching and tempering. Such as carbide, carburized steel, hardened steel, surface hardened steel, hard cast steel, aluminum alloy, copper alloy, malleable casting, mild steel, tempered steel, annealed steel, bearings and other materials.

The hardenability curve of multiple end-quenched samples can be measured automatically at one time;Measurement methods are divided into: general hardenability steel, low hardenability steel;

High degree of automation, full automatic test process:

The screw automatically up and down,

Automatic sample movement for multi-sample multi-point measurement

Accurate position control, repeatability of measuring position movement: 0.01mm; Running accuracy: 0.01mm;

Single measurement, batch measurement, ASTM/ national standard hardness conversion table;

Automatic out-of-range alarm; Show the number of the unqualified part;

The minimum measurable thickness of the sample is automatically displayed;

Hardness test database query;

Automatically generate customized inspection reports and plot sample hardenability curves.

Test Force: 60kg, 100kg, 150kg, 15kg,30kg,45kg

Test force accuracy : ±1%

Measuring range: 20-88HRA, 20-100HRB, 20-70HRC 70-91HR15N,42-80HR30N,20-70HR45N,

73-93HR15T,43-82HR30T,12-72HR45T

Indenter type : Rockwell diamond indenter , 1.588mm steel ball indenter

Test space :

Maximum allowable height of sample: 120 mm

Distance from indenter center to machine wall: 170 mm

Initial test force :0.1-50sec

Total test force :0.1-50sec

Operation mode :The screw automatically , the initial test force and the main test force are automatically applied

Display :8 inch HD touch screen, menu selection, hardness value display, parameter setting, data statistics, storage, etc

The display resolution : 0.1HR

Measurement scale : HRA, HRD, HRC, HRFW, HRBW, HRGW, HRHW, HREW, HRKW, HRL, HRM, HRP, HRR, HRS, HRV,HR15N、HR30N、HR45N、HR15T、HR30T、HR45T

Conversion scale : A hardness conversion scale for a variety of materials according to ASTM E140 standards

Data statistics : test times, average value, maximum value, minimum value, repeatability, set the upper and lower limits of hardness value, with warning function

Data output USB interface: RS232 interface

Power : AC220V, 50Hz

Implement standard : ISO6508, ASTME18, JISZ2245, GB/T230.2

|

Main Machine |

1Set |

diamond Rockwell indenter |

1 PC |

|

Φ1.588mm ball indenter |

1 PC |

XY automatic table |

1 PC |

|

Rockwell hardness tester block |

3 PC |

Surface Rockwell hardness block |

2 PC |

|

power cable |

1 PC |

set of text data |

1 PC |

|

Dust cover |

1 PC |

|