The hardness at the location around the weld can help evaluate the brittleness of the weld, thereby helping you determine whether the weld has the required strength, so the weld Vickers hardness testing method is a method that helps evaluate the quality of the weld.

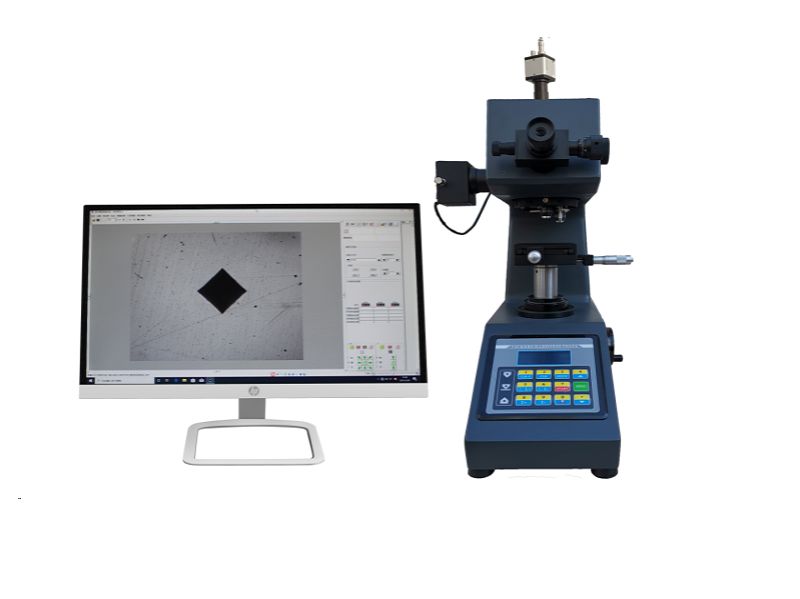

Shandong Shancai /Laizhou Laihua Testing Instrument Company's Vickers hardness tester can perform hardness testing on welded parts or welding areas. When testing the hardness of a welding point, multi-point measurements will be made at a certain distance from the edge of the sample or the top of the welding point. After obtaining the multi-point indentation, the hardness value can be measured by continuous measurement and a curve graph can be obtained.

When using a Vickers hardness tester to test welded parts, the following test conditions should be noted:

1. Flatness of the sample: Before testing, we grind the weld to be tested to make its surface smooth, free of oxide layer, cracks and other defects.

2. On the center line of the weld, take a point on the curved surface every 100 mm for testing.

3. Choosing different test forces will result in different results, so we must choose the appropriate test force before testing.

The microhardness tester has requirements for the surface finish of the tested sample, which needs to be carefully prepared according to the metallographic sample.

The microhardness test principle in the microhardness test method is exactly the same as the Vickers hardness, but the load used is smaller than the low-load Vickers hardness, usually less than 1000g, and the resulting indentation is only a few microns to a few two microns, so the microhardness test provides a very convenient means for studying the microstructure properties of the permeable layer. It is widely used to determine the hardness of each phase on the surface and in the permeating layer.

The symbol of microhardness is usually expressed by HV, and its determination principle and method are similar to the Vickers hardness method. The loading system, measuring system and indenter precision of microhardness tester are more demanding than that of low-load Vickers hardness tester. At present, microhardness tester is widely used in thin workpieces, and because the magnification can reach 400 times, it is often used as a simple metallographic microscope.

In the process of use, attention should be paid to the load, micrometer and indenter of the microhardness tester, which should be checked in before use, and the hardness block is used for comprehensive identification of its indicating value.

The microhardness tester applies the load in the test operation as smooth and uniform as possible, without impact and vibration. In order to ensure the accuracy of the test results, it is usually necessary to measure several times in different parts, and find the average value to represent the hardness value of the permeability test layer or alloy phase. For the infiltration layer used at high temperature, its hardness can be measured by using a high temperature microhardness tester.

Post time: Apr-10-2024