1 Preparation before testing

1) The hardness tester and indenter used for Vickers hardness testing should comply with the provisions of GB/T4340.2;

2) The room temperature should generally be controlled within the range of 10~35℃. For tests with higher precision requirements, it should be controlled at (23±5)℃.

2 Samples

1) The sample surface should be flat and smooth. It is recommended that the sample surface roughness should meet the requirements: Maximum value of surface roughness parameter: Vickers hardness sample 0.4 (Ra)/μm; small load Vickers hardness sample 0.2 (Ra)/μm; micro Vickers hardness sample 0.1 (Ra)/μm

2) For small load Vickers and micro Vickers samples, it is recommended to select appropriate polishing and electrolytic polishing for surface treatment according to the type of material.

3) The thickness of the sample or test layer should be at least 1.5 times the diagonal length of the indentation

4) When using small load and micro Vickers for testing, if the sample is very small or irregular, the sample should be inlaid or clamped with a special fixture before testing.

3Test method

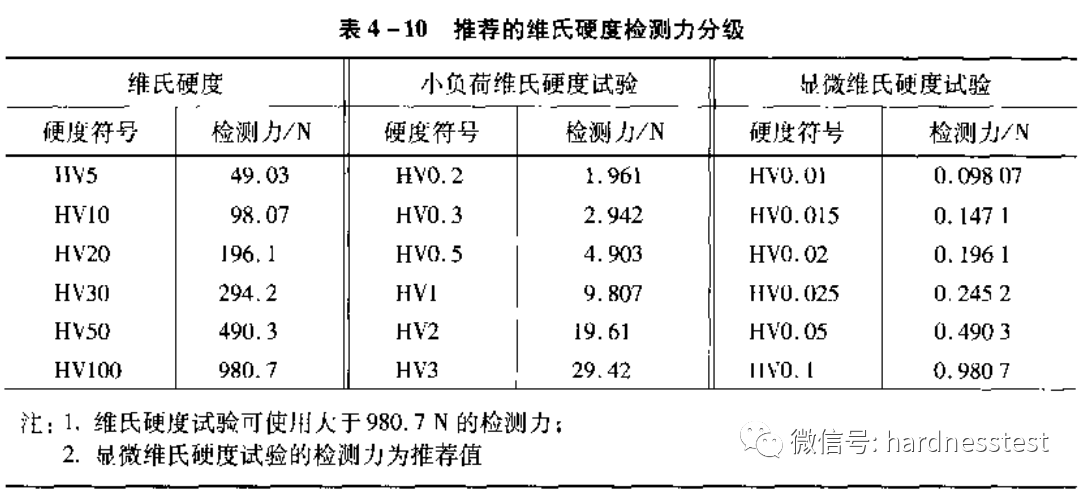

1) Selection of test force: According to the hardness, thickness, size, etc. of the sample, the test force shown in Table 4-10 should be selected for the test. .

2) Test force application time: The time from the start of force application to the completion of the full test force application should be within 2 ~ 10 s. For small load Vickers and micro Vickers hardness tests, the indenter descending speed should not exceed 0.2 mm/s. The test force holding time is 10~15 s. For particularly soft materials, the holding time can be extended, but the error should be within 2.

3) Distance from the center of the indentation to the edge of the sample: Steel, copper and copper alloys should be at least 2.5 times the diagonal length of the indentation; light metals, lead, tin and their alloys should be at least 3 times the diagonal length of the indentation. The distance between the centers of two adjacent indentations: for steel, copper and copper alloys, it should be at least 3 times the length of the diagonal line of the stop mark; for light metals, lead, tin and their alloys, it should be at least 6 times the length of the diagonal line of the indentation

4) Measure the arithmetic mean of the lengths of the two diagonals of the indentation, and find the Vickers hardness value according to the table, or calculate the hardness value according to the formula.

The difference in the length of the two diagonals of the indentation on the plane should not exceed 5% of the average value of the diagonals. If it exceeds, it should be noted in the test report.

5) When testing on a curved surface sample, the results should be corrected according to the table.

6) In general, it is recommended to report the hardness test values of three points for each sample.

4 Vickers hardness tester classification

There are 2 types of commonly used Vickers hardness testers. The following is an introduction to the commonly used Vickers hardness tester usage:

1. Eyepiece measurement type;

2. Software measurement type

Classification 1: Eyepiece measurement type Features: Use eyepiece to measure. Usage: The machine makes a (diamond ◆) indentation, and the diagonal length of the diamond is measured with an eyepiece to obtain the hardness value.

Classification 2: Software measurement type:Features: Use hardness software to measure; convenient and easy on the eyes; can measure hardness, length, save indentation pictures, issue reports, etc. Usage: The machine makes a (diamond ◆) indentation, and the digital camera collects the indentation on the computer, and the hardness value is measured on the computer.

5 Software classification: 4 basic versions, automatic turret control version, semi-automatic version, and fully automatic version.

1. Basic version

Can measure hardness, length, save indentation pictures, issue reports, etc.;

2.Control automatic turret version software can control the hardness tester turret, such as, objective lens, indenter, loading, etc.;

3.Semi-automatic version with electric X-Y test table, 2D platform control box; In addition to the automatic turret version function, the software can also set the spacing and points, automatic dotting, automatic measurement, etc.;

4.Fully automatic version with electric X-Y test table, 3D platform control box, Z-axis focus; In addition to the semi-automatic version function, the software also has a Z-axis focus function;

6 How to choose a suitable Vickers hardness tester

The price of Vickers hardness tester will vary depending on the configuration and function.

1. If you want to choose the cheapest, then you can choose:

Equipment with a small LCD screen and manual diagonal input through the eyepiece;

2. If you want to choose a cost-effective device, then you can choose:

Equipment with a large LCD screen, an eyepiece with a digital encoder, and a built-in printer;

3. If you want a more upscale device, then you can choose:

Equipment with a touch screen, a closed-loop sensor, an eyepiece with a printer (or USB flash drive), a worm gear lifting screw, and a digital encoder;

4. If you think it is tiring to measure with an eyepiece, then you can choose:

Equipped with a CCD hardness image processing system, measure on a computer without looking at the eyepiece, which is convenient, intuitive, and fast. You can also generate reports and save indentation pictures, etc.

5. If you want simple operation and high automation, then you can choose:

Automatic Vickers hardness tester and fully automatic Vickers hardness tester

Features: set the spacing and number of points, automatically and continuously dot, and automatically measure.

Post time: Oct-17-2024