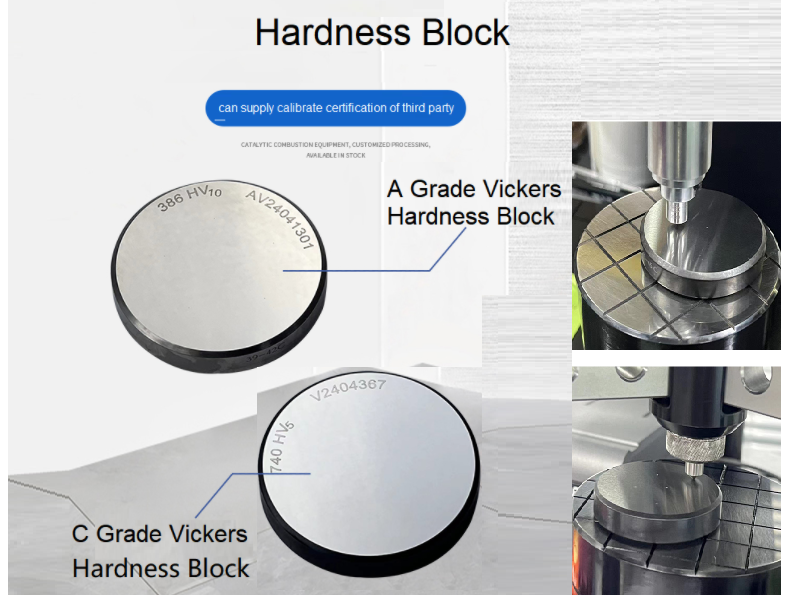

For many customers who have high requirements for the accuracy of hardness testers, the calibration of hardness testers places increasingly stringent demands on hardness blocks. Today, I am delighted to introduce the series of Class A hardness blocks.—Rockwell hardness blocks, Vickers hardness blocks, Brinell Hardness blocks, HRA, HRB, HRC, HRE HRR, HV, HBW etc.

Class A hardness blocks are subject to much stricter requirements in terms of processing techniques, surface treatment, and heat treatment processes. The manufacturing process of these hardness blocks involves advanced machining methods. State-of-the-art CNC machining centers are employed to ensure that the dimensions of the hardness blocks meet extremely precise standards. Each cutting parameter is carefully adjusted to minimize any potential dimensional errors.

In the aspect of surface treatment, special surface finishing techniques are utilized. Chemical polishing and precision lapping are carried out to create a surface with an extremely low roughness. This not only reduces the interference of surface irregularities during the hardness measurement process but also enhances the adhesion between the indenter of the hardness tester and the surface of the hardness block, ensuring more accurate measurement results.

The heat treatment process of Class A hardness blocks is also meticulously controlled. Advanced heat treatment furnaces with precise temperature control systems are used. During the heat treatment process, the heating rate, holding time, and cooling rate are all strictly regulated according to a specific process curve. This ensures that the internal structure of the hardness block is uniform and stable, effectively reducing the internal stress within the material.

Thanks to these rigorous processes, the measurement uncertainty of Class A hardness blocks is significantly reduced, and their uniformity is remarkably higher compared to other types of hardness blocks. They provide a more reliable basis for the calibration of hardness testers, enabling hardness testers to achieve higher accuracy and stability in their measurements. Whether in industrial production, quality control in laboratories, or scientific research fields, Class A hardness blocks play an indispensable and crucial role, helping professionals obtain more accurate and trustworthy hardness measurement data.

By choosing Class A hardness blocks, customers can have full confidence in the calibration of their hardness testers, ensuring that their hardness testing results are accurate and consistent, and thus providing strong support for the quality control and product development of their products.

Post time: Mar-10-2025