Preparation of rockwell hardness test :

ensure that the hardness tester is qualified, and select the appropriate workbench according to the shape of the specimen; Select the appropriate indenter and total load value.

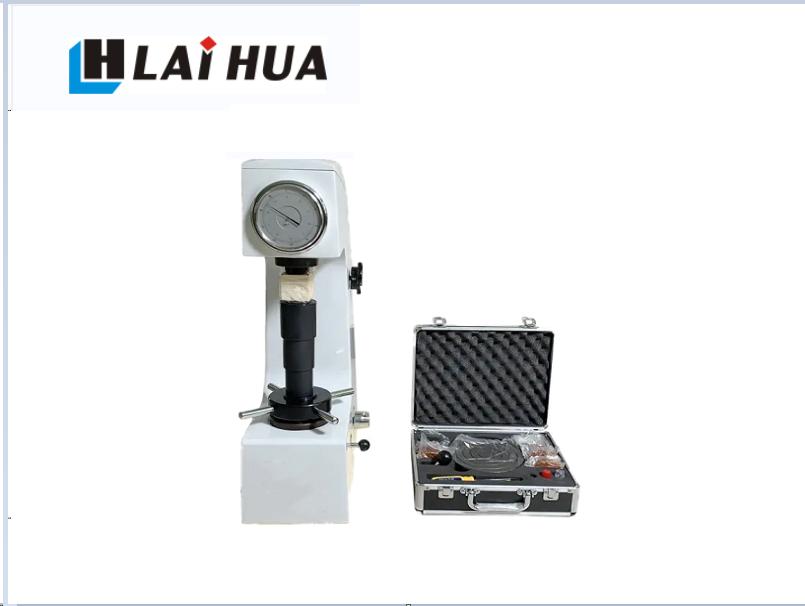

HR-150A manual Rockwell hardness tester test steps:

Step 1:

Place the specimen on the workbench, rotate the handwheel to slowly raise the workbench, and push up the indenter 0.6mm, the small pointer of the indicator dial refers to the "3", the large pointer refers to the mark c and b (slightly less than the dial can be rotated until the alignment).

Step 2 :

After the pointer position is aligned, you can pull the loading handle forward to apply the main load to the press head.

Step 3 :

When the rotation of the indicator pointer stops obviously, the unloading handle can be pushed back to remove the main load.

Step 4 :

Read the corresponding scale value from the indicator. When the diamond indenter is used, the reading is in black character on the outer ring of the dial;

When the steel ball indenter is used, the value is read by the red letter on the inner ring of the reading dial。

Step 5 :

After loosening the handwheel and lowering the workbench, you can move the specimen slightly and select a new position to continue the test.

Note : When using the HR-150A Rockwell hardness meter, it is necessary to pay attention to keep the hardness meter clean and avoid collision and friction, so as not to affect the measurement accuracy.

Post time: Mar-14-2024