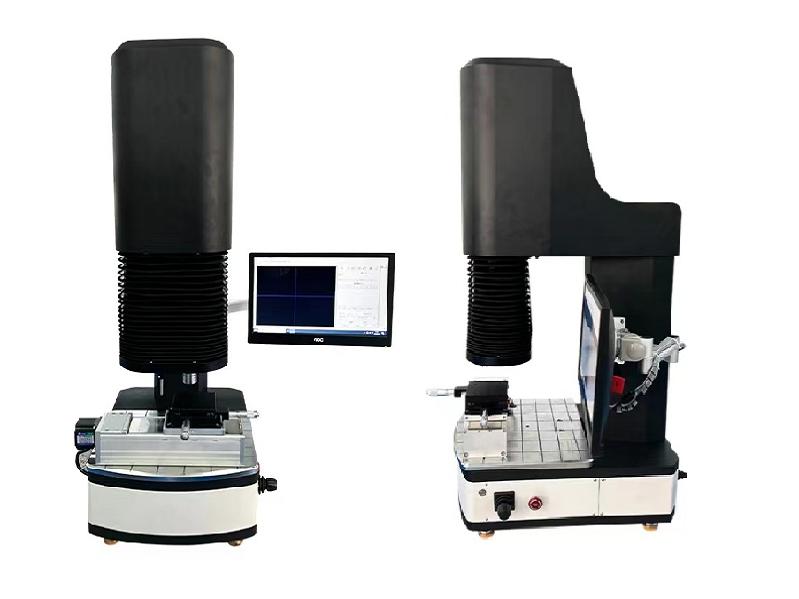

Usually, the higher the degree of automation in Vickers hardness testers , the more complex the instrument . Today, we will introduce a fast and easy-to-operate micro Vickers hardness tester.

The main machine of the hardness tester replaces the traditional screw lifting structure with the machine head automatic up and down, and the fixed workpiece working table, so that this series of machines can provide more convenient online testing solutions.

Cell load control of this machine replaces the traditional weight load force control system, reduced the probability of failure caused by the weight force part of the instrument.

The instrument is equipped with an automatic measurement system to digitally image the hardness indentation on the computer screen, and then obtain the hardness value through automatic and manual measurement methods.

This machine is equipped with a manual XY workbench, and can also be equipped with an XY automatic loading platform and a fully automatic measurement system to achieve automatic dotting, multi-point automatic measurement, panoramic scanning and other functions.

This series of products can choose different test force levels and automation configurations. If you have any questions, please feel free to contact us.

Today we introduce an instrument for measuring the hardness of grooved products with an extended indenter, telephoto objective lens. This instrument is a microscopic Vickers hardness tester specially customized for customers' grooved products. In order to meet the testing requirements of customers' special workpieces, the equipment has changed the mechanical movement mode, and the test force loading process is completed by the up and down lifting of the machine head. It is also equipped with an extended Vickers indenter and a telephoto objective lens, which simplifies the testing process of customers' grooved workpieces and ensures the test accuracy. If you have any questions about hardness testing, please feel free to contact Laizhou Laihua

Post time: Jul-25-2024