The code for metal hardness is H. According to different hardness test methods, the conventional representations include Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), Shore (HS) hardness, etc., among which HB and HRC are more commonly used. HB has a wider range of applications, and HRC is suitable for materials with high surface hardness, such as heat treatment hardness. The difference is that the indenter of the hardness tester is different. The Brinell hardness tester is ball indenter, while the Rockwell hardness tester is a diamond indenter.

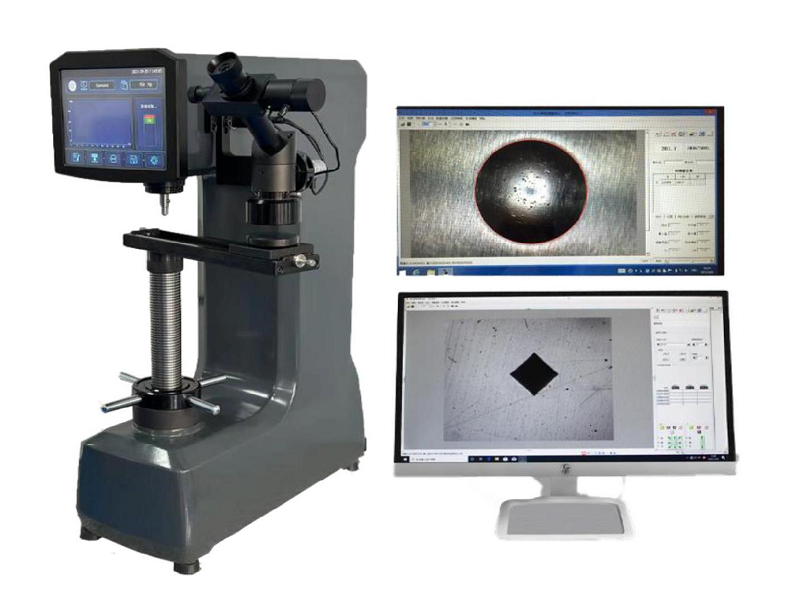

HV-suitable for microscope analysis. Vickers hardness (HV) Press the material surface with a load of less than 120kg and a diamond square cone indenter with a vertex angle of 136°. The surface area of the material indentation pit is divided by the load value, which is the Vickers hardness value (HV). Vickers hardness is expressed as HV (refer to GB/T4340-1999), and it measures extremely thin samples.

HL portable hardness tester is convenient for measurement. It uses the impact ball head to impact the hardness surface and produce a bounce. The hardness is calculated by the ratio of the rebound speed of the punch at 1mm from the sample surface to the impact speed. The formula is: Leeb hardness HL=1000×VB (rebound speed)/VA (impact speed).

Portable Leeb hardness tester can be converted into Brinell (HB), Rockwell (HRC), Vickers (HV), Shore (HS) hardness after Leeb (HL) measurement. Or use Leeb principle to directly measure hardness value with Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), Shore (HS).

HB - Brinell hardness:

Brinell hardness (HB) is generally used when the material is softer, such as non-ferrous metals, steel before heat treatment or after annealing. Rockwell hardness (HRC) is generally used for materials with higher hardness, such as hardness after heat treatment, etc.

Brinell hardness (HB) is a test load of a certain size. A hardened steel ball or carbide ball of a certain diameter is pressed into the metal surface to be tested. The test load is maintained for a specified time, and then the load is removed to measure the diameter of the indentation on the surface to be tested. The Brinell hardness value is the quotient obtained by dividing the load by the spherical surface area of the indentation. Generally, a hardened steel ball of a certain size (usually 10mm in diameter) is pressed into the material surface with a certain load (usually 3000kg) and maintained for a period of time. After the load is removed, the ratio of the load to the indentation area is the Brinell hardness value (HB), and the unit is kilogram force/mm2 (N/mm2).

Rockwell hardness determines the hardness value index based on the plastic deformation depth of the indentation. 0.002 mm is used as a hardness unit. When HB>450 or the sample is too small, the Brinell hardness test cannot be used and Rockwell hardness measurement is used instead. It uses a diamond cone with a vertex angle of 120° or a steel ball with a diameter of 1.59 or 3.18mm to press into the surface of the material under test under a certain load, and the hardness of the material is calculated from the depth of the indentation. According to the hardness of the test material, it is expressed in three different scales:

HRA: It is the hardness obtained by using a 60kg load and a diamond cone indenter, which is used for materials with extremely high hardness (such as cemented carbide, etc.).

HRB: It is the hardness obtained by using a 100kg load and a hardened steel ball with a diameter of 1.58mm, which is used for materials with lower hardness (such as annealed steel, cast iron, etc.).

HRC: It is the hardness obtained by using a 150kg load and a diamond cone indenter, which is used for materials with very high hardness (such as hardened steel, etc.).

In addition:

1.HRC means Rockwell hardness C scale.

2.HRC and HB are widely used in production.

3.HRC applicable range HRC 20-67, equivalent to HB225-650,

If the hardness is higher than this range, use Rockwell hardness A scale HRA,

If the hardness is lower than this range, use Rockwell hardness B scale HRB,

The upper limit of Brinell hardness is HB650, which cannot be higher than this value.

4.The indenter of Rockwell hardness tester C scale is a diamond cone with a vertex angle of 120 degrees. The test load is a certain value. The Chinese standard is 150 kgf. The indenter of Brinell hardness tester is a hardened steel ball (HBS) or a carbide ball (HBW). The test load varies with the diameter of the ball, ranging from 3000 to 31.25 kgf.

5.The Rockwell hardness indentation is very small, and the measured value is localized. It is necessary to measure several points to find the average value. It is suitable for finished products and thin slices and is classified as non-destructive testing. The Brinell hardness indentation is larger, the measured value is accurate, it is not suitable for finished products and thin slices, and is generally not classified as non-destructive testing.

6. The hardness value of Rockwell hardness is an unnamed number without units. (Therefore, it is incorrect to call Rockwell hardness as a certain degree.) The hardness value of Brinell hardness has units and has a certain approximate relationship with tensile strength.

7. Rockwell hardness is directly displayed on the dial or digitally displayed. It is easy to operate, fast and intuitive, and suitable for mass production. Brinell hardness requires a microscope to measure the indentation diameter, and then look up the table or calculate, which is more cumbersome to operate.

8. Under certain conditions, HB and HRC can be interchanged by looking up the table. The mental calculation formula can be roughly recorded as: 1HRC≈1/10HB.

Hardness test is a simple and easy test method in mechanical property test. In order to use hardness test to replace certain mechanical property tests, a more accurate conversion relationship between hardness and strength is required in production.

Practice has proved that there is an approximate corresponding relationship between various hardness values of metal materials and between hardness value and strength value. Because the hardness value is determined by the initial plastic deformation resistance and the continued plastic deformation resistance, the higher the strength of the material, the higher the plastic deformation resistance, and the higher the hardness value.

Post time: Aug-16-2024