Hardness tester is an instrument for measuring the hardness of materials. According to the different materials being measured, hardness tester can be applied to different fields. Some hardness testers are used in the mechanical processing industry, and they mainly measure the hardness of metal materials. Such as: Brinell hardness tester, Rockwell hardness tester, Leeb hardness tester, Vickers hardness tester, microhardness tester, Shore hardness tester, Webster hardness tester etc. The specific application scopes of these hardness testers are as follows:

Brinell hardness tester : mainly used for hardness testing of forged steel and cast iron with uneven structure. The Brinell hardness of forged steel and gray cast iron has a good correspondence with the tensile test. The Brinell hardness test can also be used for non-ferrous metals and soft steel. The small diameter ball indenter can measure small size and thinner materials, and measure the heat treatment wrkshops and factory inspection departments of various machinery factories. The Brinell hardness tester is mostly used for the inspection of raw materials and semi-finished products. Due to the large indentation, it is generally not used for finished product inspection.

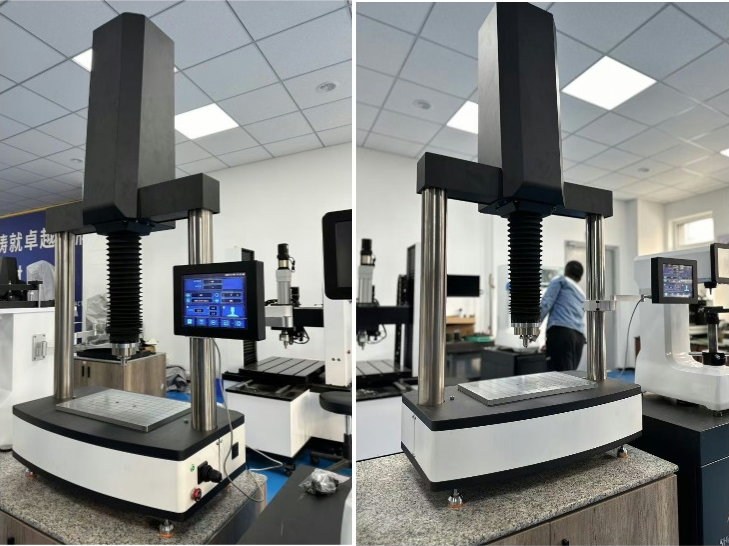

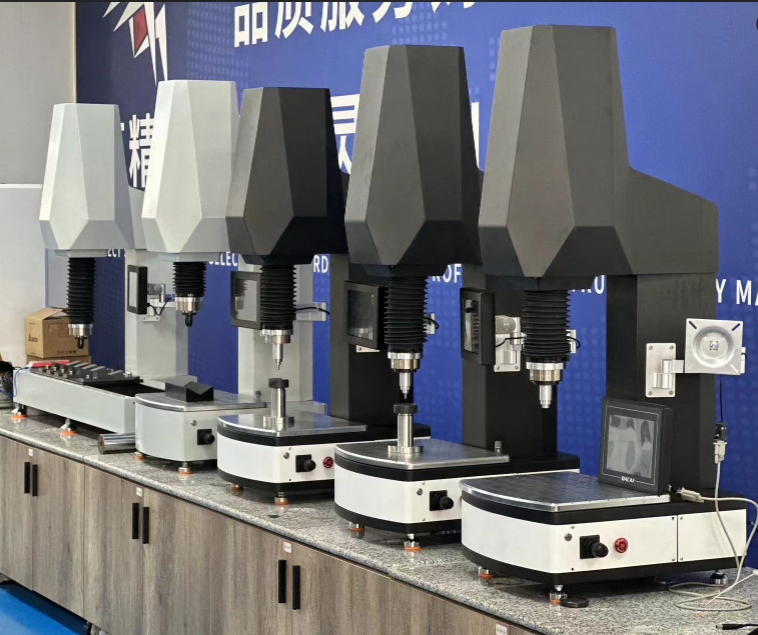

Rockwell hardness tester : Test various ferrous and non-ferrous metals, test the hardness of quenched steel, quenched and tempered steel, annealed steel, case-hardened steel, plates of various thicknesses, carbide materials, powder metallurgy materials, thermal spray coatings, chilled castings, forgeable castings, aluminum alloys, bearing steel, hardened thin steel plates, etc.

Superficial Rockwell Hardness Tester : Used to test the hardness of thin sheet metal, thin wall pipe, case hardened steel and small parts, hard alloy, carbide, case hardened steel, hardened sheet, hardened steel, quenched and tempered steel, chilled cast iron, cast iron, aluminum, copper, magnesium and other alloy steels.

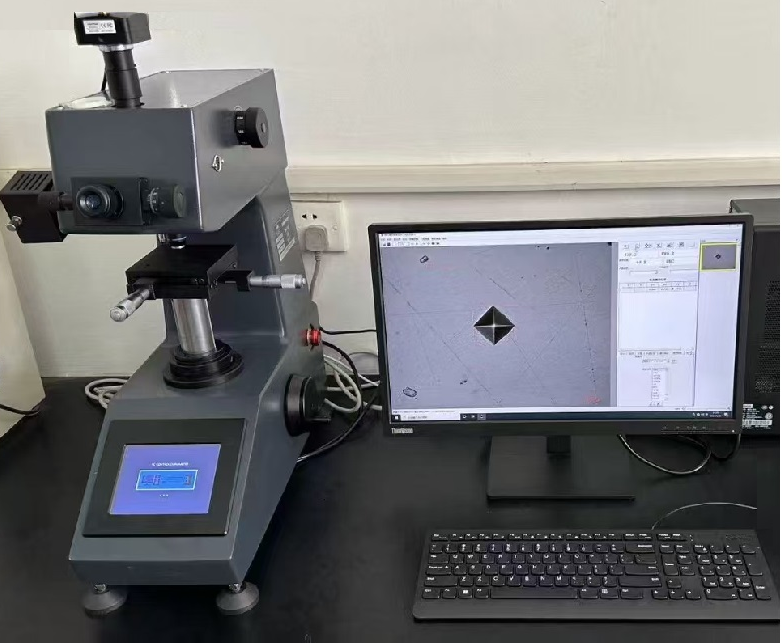

Vickers hardness tester : measure tiny parts, thin steel plates, metal foils, IC sheets, wires, thin hardened layers, electroplated layers , glass, jewelry and ceramics , ferrous metals, non-ferrous metals, IC sheets, surface coatings, laminated metals; glass, ceramics, agate, gemstones, etc.; depth and gradient hardness test of carbonized layers and quenching hardened layers. Hardware processing, electronics industry, mold accessories, watch industry.

Knoop hardness tester : widely used to measure the microhardness of small and thin specimens, surface penetration coatings and other specimens, and to measure the Knoop hardness of brittle and hard materials such as glass, ceramics, agate, artificial gemstones, etc., applicable scope: heat treatment, carburization, quenching hardening layer, surface coating, steel, non-ferrous metals and small and thin parts, etc.

Leeb hardness tester : steel and cast steel, alloy tool steel, gray cast iron, ductile iron, cast aluminum alloy, copper-zinc alloy (brass), copper-tin alloy (bronze), pure copper, forged steel, carbon steel, chrome steel, chrome-vanadium steel, chrome-nickel steel, chrome-molybdenum steel, chrome-manganese-silicon steel, ultra-high strength steel, stainless steel, etc.

Shore hardness tester : Mainly used to measure the hardness of soft plastics and conventional hardness rubber, such as soft rubber, synthetic rubber, printing rubber rollers, thermoplastic elastomers, leather, etc. It is widely used in the plastics industry, rubber industry and other chemical industries , including the hardness of hard plastics and hard rubber, such as thermoplastic hard resins, floor materials, bowling balls, etc. It is particularly suitable for on-site hardness measurement of rubber and plastic finished products.

Webster hardness tester : used to test aluminum alloy, soft copper, hard copper, super hard aluminum alloy and soft steel.

Barcol Hardness Tester : Simple and convenient, this instrument has become a standard in the field or raw material testing of final products, such as fiberglass boards, plastics, aluminum and related materials. This instrument meets the requirements of the American Fire Protection Association NFPA1932 and is used for field testing of fire stairs in high temperatures. Measuring materials: aluminum, aluminum alloys, soft metals, plastics, fiberglass, fire ladders, composite materials, rubber and leather.

Post time: Dec-25-2024