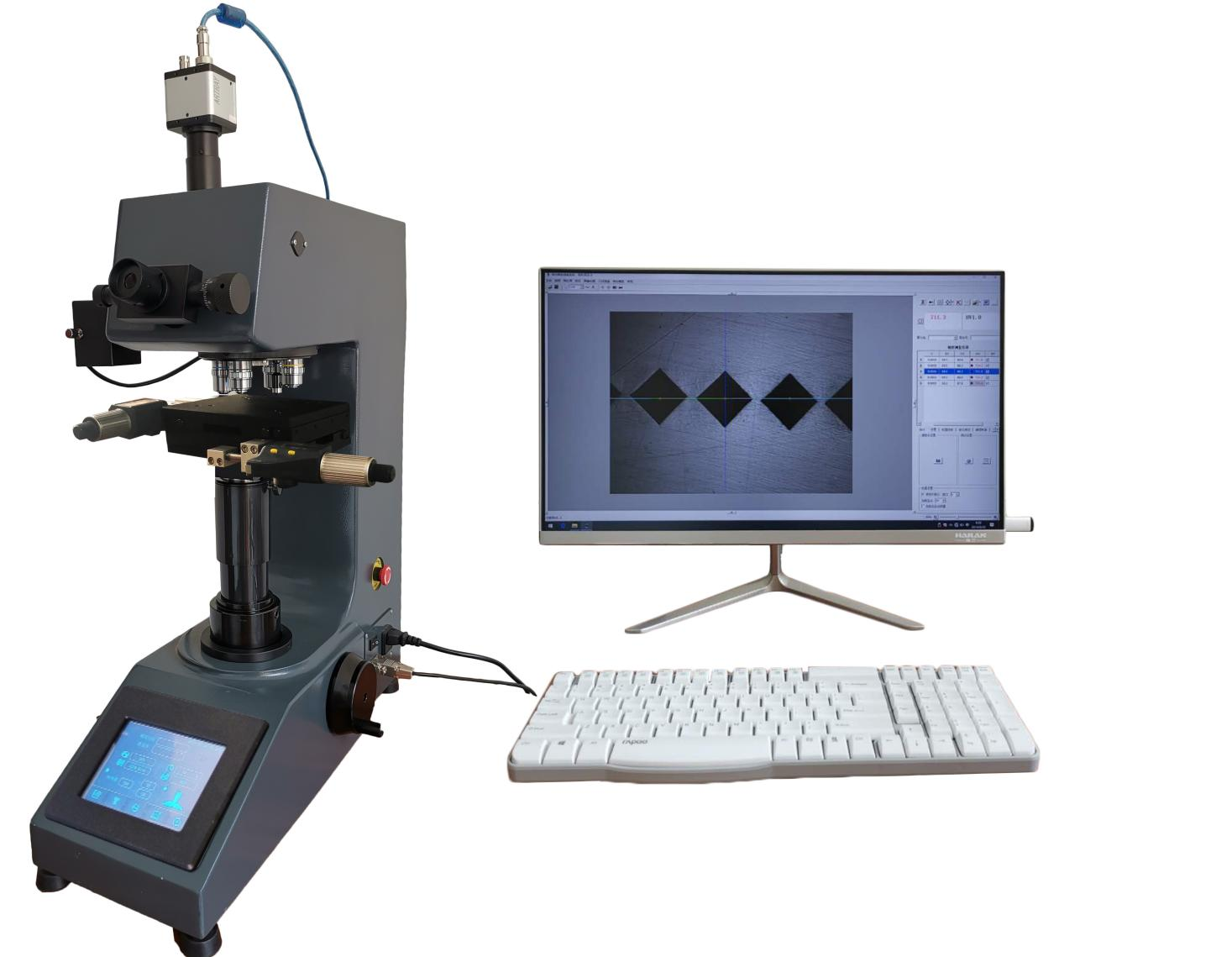

MHV-10A Three Objective Touch screen Vickers Hardness Tester

* Ergonomic large chassis, large test area (210mm Height *135mm Depth)

*Touch screen with newly developed high definition operation software; Visual and clear, easy to operate.

*Adopts load cell control system, improves the precision of the test force and the repeatability and stability of the indicating value.

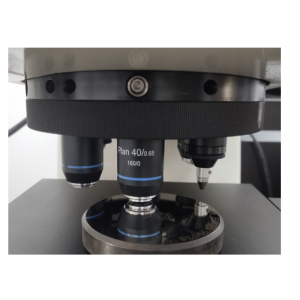

* With three objective lenses for measurement

* Precision conforms to GB/T 4340.2, ISO 6507-2 and ASTM E92

*It can be equipped with CCD image automatic measuring system via USB, RS232 or bluetooth, so as to set test force, dwell time, lens, turret and other parameters as well as achieve hardness value on the computer.

You can directly set the upper and lower limits of the hardness value, and whether the workpiece is qualified or not can be displayed according to the measured value.

* The hardness value can be converted according to national and international standards

* Every single test force can be individually calibrated to ensure the force value reaches the best state

* Data and charts can be stored into the database. At least 500 groups of data can be stored (20 data/group)

* Data output mode: RS232, USB, Bluetooth; data can be printed via miro printer, or be transmitted to computer and generate Excel report.

* The brightness of the light can be adjustable in 20 levels via sliding, which is convenient and efficient

* Optional scanning gun can scan the two-dimensional barcode on the product, and the scanned part information will be automatically saved and grouped.

Measuring range:5-3000HV

Test force: 2.942,4.903,9.807, 19.61, 24.52, 29.42, 49.03, 98.07N(0.3,0.5,1,2, 2.5, 3, 5, 10kgf)

Hardness scale:HV0.3, HV0.5, HV1, HV2, HV2.5, HV3, HV5, HV10

Lens/indenters switch: motorized turret

Testing Force Application Method: Automatic loading and unloading

Reading microscope: 10X

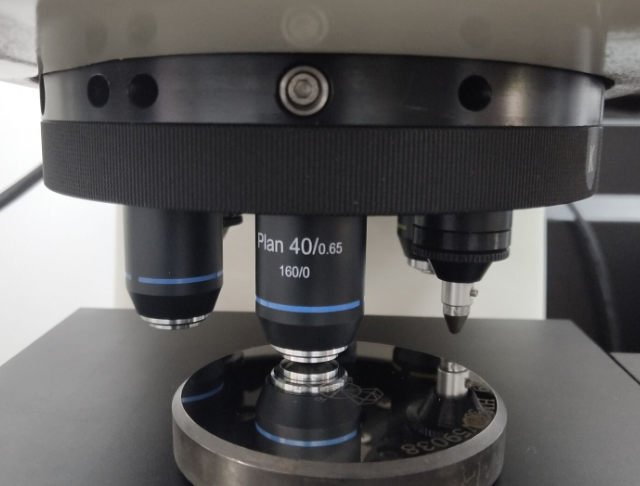

Objectives:10X, 20X,40X

Magnifications of the measuring system:100X, 200X,400X

Dwell Time: 5~60S

Light source: halogen lamp

Data output: blue tooth

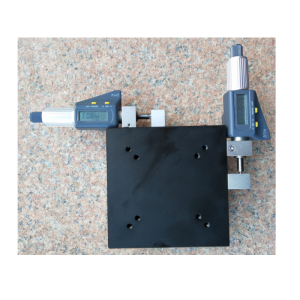

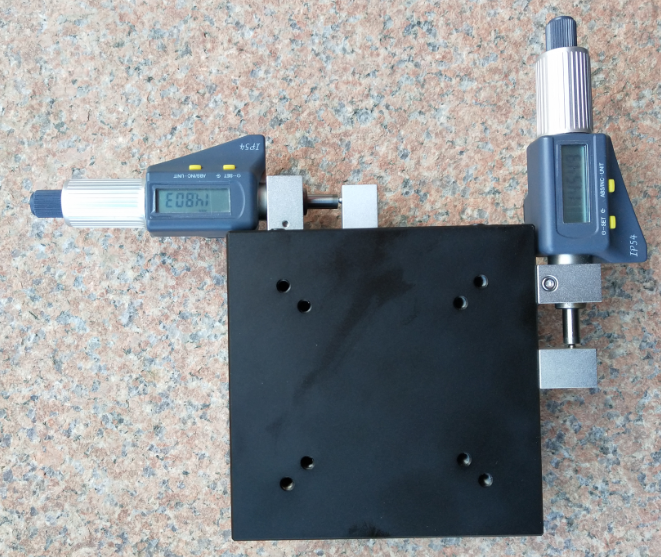

X-Y Test Table:Size: 100×100mm; Travel: 25×25mm; Resolution: 0.01mm

Max. height of test piece:210mm

Depth of throat:135mm

Power supply:220V AC or 110V AC, 50 or 60Hz

Dimensions:597x340x710mm

Weight: approx 65kg

|

Main unit 1 |

Horizontal Regulating Screw 4 |

|

Reading microscope 1 |

Level 1 |

|

10x, 20x 40X objective 1 each (with main unit) |

Fuse 1A 2 |

|

Diamond Vickers Indenter 1 (with main unit) |

Halogen Lamp 1 |

|

XY table 1 |

Power Cable 1 |

|

Hardness Block 700~800 HV10 1 |

Screw Driver 1 |

|

Hardness Block 700~800 HV1 1 |

Internal hexagonal wrench 1 |

|

Certificate 1 |

Anti-dust Cover 1 |

|

Operation Manual 1 |

Blue booth printer |