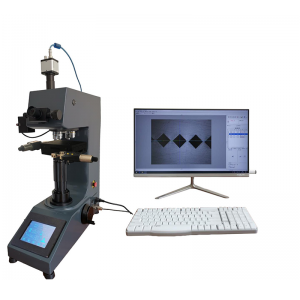

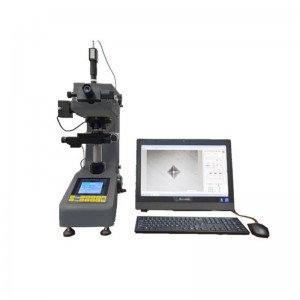

HVZ-1000A Large Micro Vickers Hardness Tester (with measuring system)

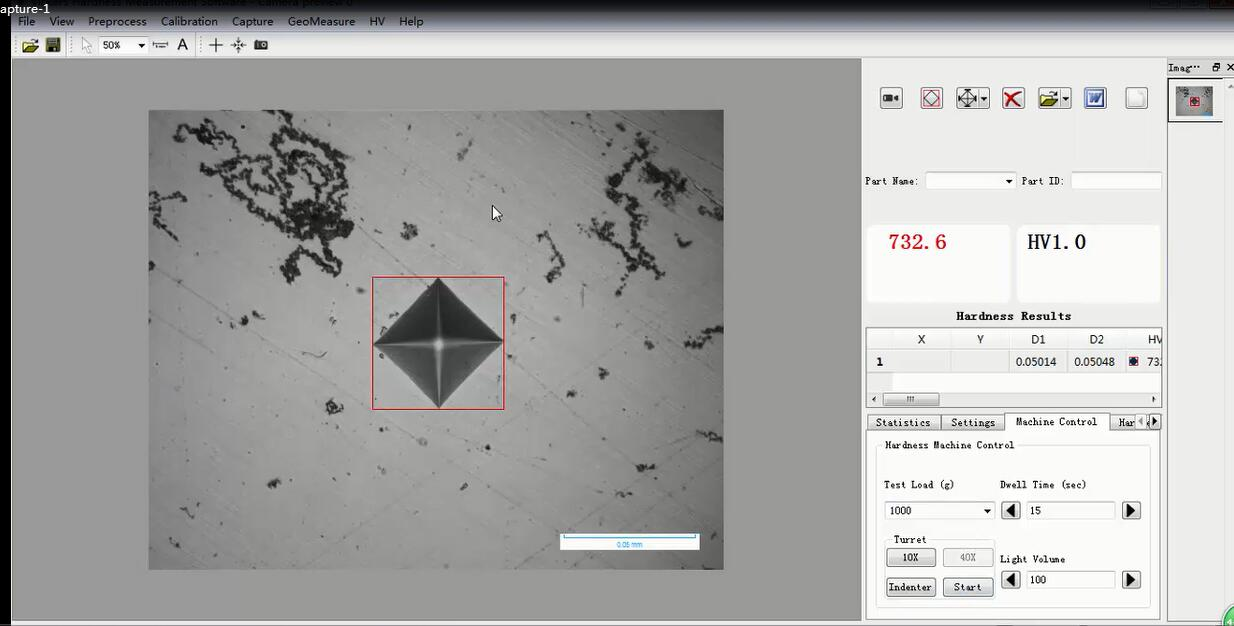

* Computerized measuring system;

* User-friendly interface, easy operation;

* All technical parameters required for testing are selected on the computer, such as measuring method,the testing force value,the indentation length,hardness value,the dwell time of the testing force ,as well as the number of measurement. Beside,it has such functions as registering year,month and date,measuring result,treating data,outputting information with printer;

* Ergonomic large chassis, large test area (230mm Height *135mm Depth)

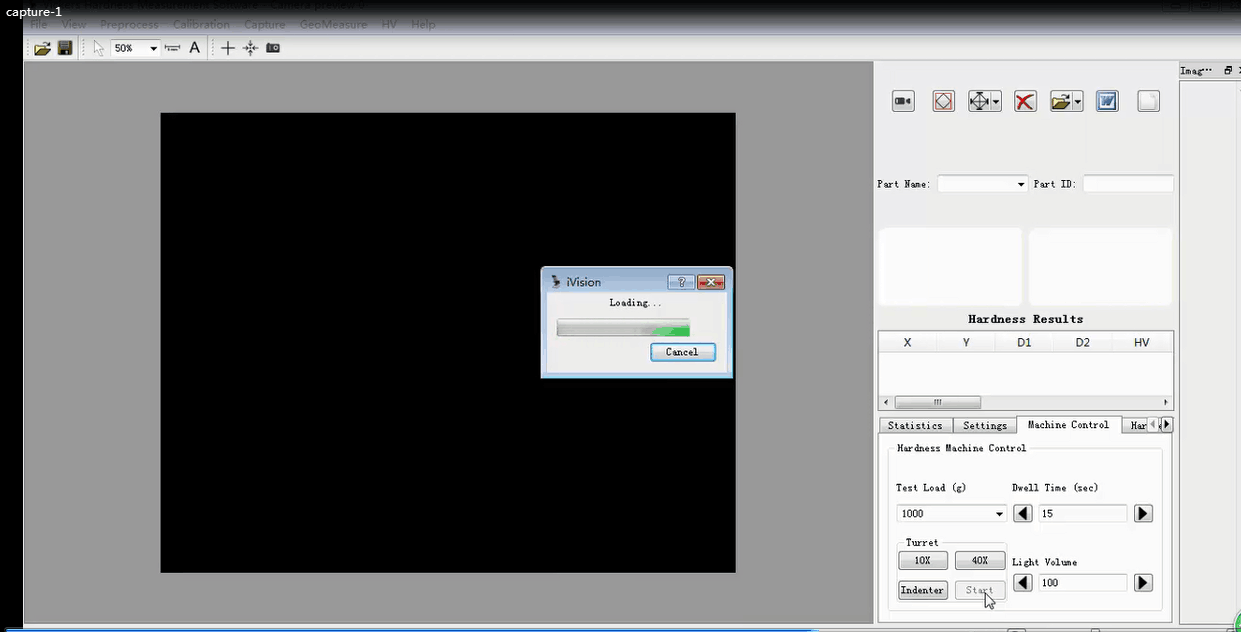

* Motorized turret for changing between indenter and lenses to guarantee the precise positioning;

* Turret for two indenters and four objectives (maximum, customized), One indenter and two objectives ( standard)

* Weight Load

* Freely adjustable dwell time from 5S to 60S

* Excecutive standard: ISO 6507,ASTM E92,JIS Z2244,GB/T 4340.2

The instrument is ideal for quality control and mechanical evaluation using vickers hardness testing method.

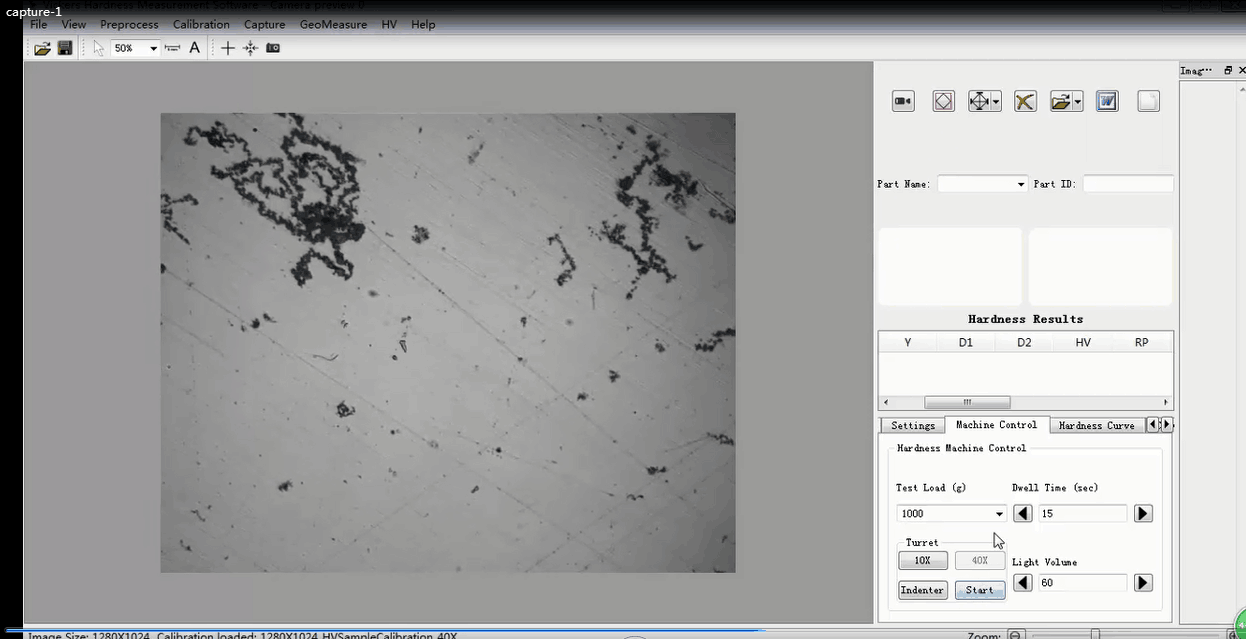

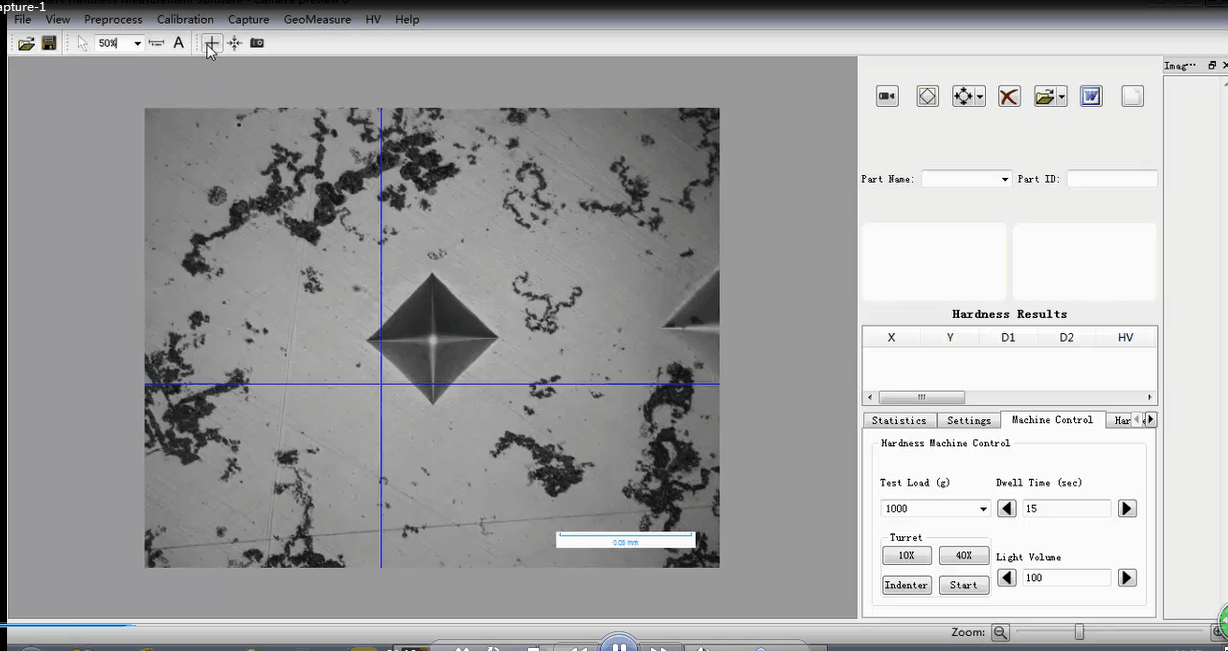

* The CCD image processing system can finish the process automatically: measurement of the diagonal length of indentation, hardness value display, testing data and image saving, etc.

* It is available to preset the upper and lower limit of hardness value, the testing result can be inspected whether it is qualified automatically.

* Proceed hardness testing on 20 test points at one time (preset the distance between test points at will), and save the testing results as one group.

* Converting between various hardness scales and tensile strength

* Inquire the saved data and image at any time

* Customer may adjust the accuracy of the measured hardness value at any time according to the calibration of Hardness Tester

* The measured HV value can be converted to the other hardness scales such as HB,HR etc.

* System provides a rich set of image processing tools for advanced users. the standard tools in the system include adjusting Brightness, Contrast, Gamma, and Histogram Level, and the Sharpen, Smooth, Invert, and Convert to Grey functions. On grey scale images, system provides various advanced tools in filtering and finding edges, as well as some standard tools in morphological operations such as Open, Close, Dilation, Erosion, Skeletonize, and Flood Fill, to name a few.

* System provides the tools to draw and measure common geometric shapes such as lines, angles 4-point angles (for missing or hidden vertexes),rectangles, circles, ellipses, and polygons. Note that the measurement assumes the system is calibrated.

* System allows user manage multiple images in an album which can be saved to and opened from an album file. The images can have the standard geometric shapes and the documents as entered by user as described above

On an image, system provides a document editor to enter/edit documents with contents either in simple plain test format or in advanced HTML format with objects including tabs, list, and images.

*System can print the image with user specified magnification if it is calibrated.

Measuring range:5-3000HV

Test force:0.098N(10gf), 0.245N(25gf), 0.49N(50gf), 0.9807N(100gf), 1.961N(200gf), 2.942N(300gf), 4.903N(500gf), 9.807N(1000gf)

Hardness scale:HV0.01, HV0.025, HV0.05, HV0.1, HV0.2, HV0.3,HV0.5,HV1

Testing Force Application Method: Automatic loading and unloading

Dwell time of the test force: 0-60S (5 seconds as a unit with optional key-in)

Magnifications of the measuring system: 400X, 100X

Min. scale value of the optical micrometer:0.0625μm

Max. height of test piece:230mm

Depth of throat:135mm

Power supply:220V AC or 110V AC, 50 or 60Hz

Dimensions:597x340x710mm

Weight: approx 65kg

|

Main unit 1 |

CCD Image Measuring System 1 |

|

Reading microscope 1 |

Computer 1 |

|

10x, 40x objective 1 each (with main unit) |

Horizontal Regulating Screw 4 |

|

Diamond Micro Vickers Indenter 1 (with main unit) |

Level 1 |

|

Weight 6 |

Fuse 1A 2 |

|

Weight Axis 1 |

Halogen Lamp 1 |

|

XY table 1 |

Power Cable 1 |

|

Flat Clamping Test Table 1 |

Screw Driver 2 |

|

Thin Specimen Test Table 1 |

Hardness Block 400~500 HV0.2 1 |

|

Filament Clamping Test Table 1 |

Hardness Block 700~800 HV1 1 |

|

Certificate |

Horizontal Regulating Screw 4 |

|

Operation manual 1 |

Anti-dust Cover 1 |

1. Find the clearest interface of the work piece

2.Load, dwell and unload

3. Adjust the focus

4. Measure to get the hardness value