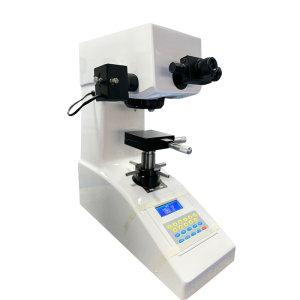

HV-10/HV-10Z Vickers Hardness Tester

1. The optical system designed by the optical engineer not only has clear images, but also can be used as a simple microscope, with adjustable brightness, comfortable vision, and not easy to fatigue after long-term operation;

2. On the industrial display screen, the hardness value can be visually displayed, the hardness can be converted, the test method, the test force, the time of the charge and the number of measurements, and the test process can be intuitively understood.

3, Cast aluminum shell molding, the structure is stable and not deformed, high-grade automotive paint, anti-scratch ability, use for many years is still bright as new;

4. Our company has its own R&D, production and processing capabilities. Our machines provide parts replacement and maintenance upgrade services for life.

1. Iron and steel, non-ferrous metals, metal foils, hard alloys, metal sheets, microstructures, carbonization;

2. Carburizing, nitriding and decarburization layers, surface hardened layer, plating layer, coating, Heat treatment;

3, glass, wafers, ceramic materials;

Technical Parameter:

Measuring range:5-3000HV

Test force:

0.3kgf(2.94N),0.5kgf(4.9N),1.0Kgf(9.8N)、3.0Kgf(29.4N)、5.0Kgf(49.0N)、10Kgf(98.0N)

Hardness scale:HV0.3,HV0.5,HV1.0,HV3.0,HV5.0,HV10.0

Lens/indenters switch: HV-10: with hand turret

HV-10Z: with auto turret

Reading microscope: 10X

Objectives: 10X, 20X

Magnifications of the measuring system:100X, 200X

Effective field of view: 800um

Min. Measuring Unit: 1um

Light source: Halogen lamp

Max. height of test piece:165mm

Depth of throat:130mm

Power supply:220V AC , 50Hz

Dimensions:585×200×630 mm

G.W./N.W.: 42Kgs/60Kgs

|

Main unit 1 |

Horizontal Regulating Screw 4 |

|

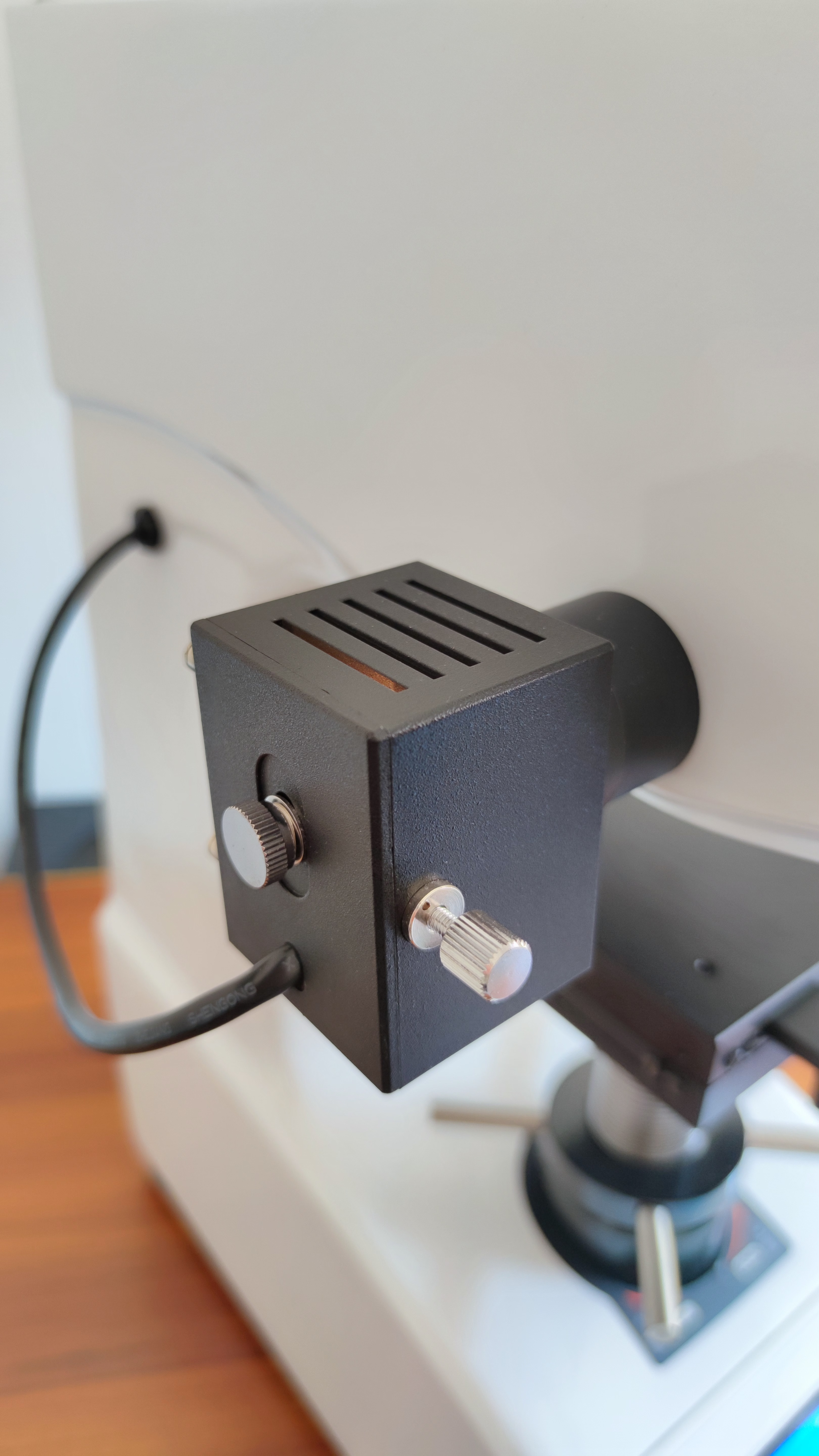

10x Reading microscope 1 |

Level 1 |

|

10x, 20x objective 1 each (with main unit) |

Fuse 2A 2 |

|

Diamond Vickers Indenter 1 (with main unit) |

Lamp 1 |

|

Weight 3 |

Power Cable 1 |

|

Hardness Block 2 |

Anti-dust Cover 1 |

|

Certificate 1 |

Operation Manual 1 |