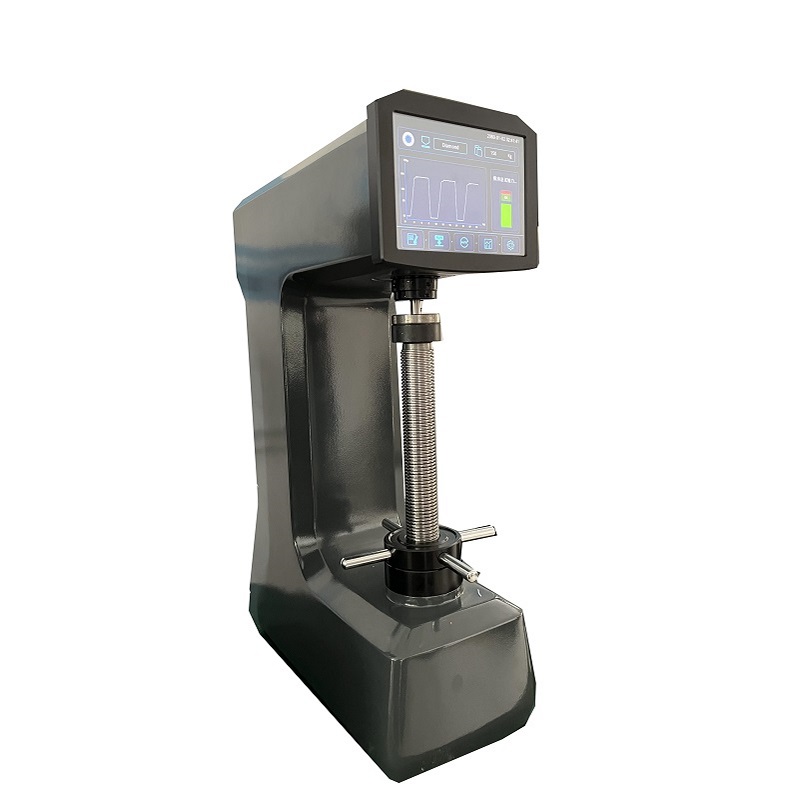

HRB-150TS Plastic Ball Indentation Hardness Tester

The ball indentation hardness tester is designed and manufactured according to the requirements of GB3398.1-2008 Plastic Hardness Determination Part 1 Ball Indentation Method and ISO 2039-1-2001 Plastic Hardness Determination Part 1 Ball Pressure Method.

Standard ISO 2039-2 describes determination of the hardness value with a Rockwell hardness testing machine, using Rockwell hardness scales E, L, M and R, similar to the Rockwell method.

This ball indentation hardness tester can be used to test the hardness of materials in automotive engineering plastics, hard rubber, plastic building materials and other industries, and can process and print the data.

Plastic hardness refers to the ability of a plastic material to resist being pressed into it by another rigid object that is considered not to undergo elastic and plastic deformation.

The indentation hardness test of plastic ball is to use a steel ball with a specified diameter to vertically press into the surface of the sample under the action of the test load, and to read the indentation depth after holding for a certain time. The hardness value is obtained by calculating or looking up the table.

1, the thickness of the sample is not less than 4mm, the loading speed can be adjusted within 2-7 seconds, usually 4-6 seconds, and the loading time is 30 seconds or 60 seconds; The load size should be selected according to the expected hardness of the sample, and the higher hardness can choose a larger load; Otherwise, the smaller load is used. If the hardness of the sample can not be predicted, it must be gradually upgraded from a small load, so as not to damage the ball indenter and the sample; Generally, the test can be carried out as long as the load is selected according to the specified requirements of the sample.

2, ball indentation hardness refers to the specified diameter of the steel ball, under the action of the test load vertically pressed into the surface of the sample, maintain a certain time, the average pressure per unit area to Kgf/mm2 or N/mm2 expressed

Initial load: 9.8N

Test load: 49N, 132N, 358N, 612, 961N

Indenter diameter: Ф 5mm, Ф 10mm

Indentation depth indication minimum scale value: 0.001mm

Timing range: 1-99S

Indication accuracy: ± 1%

Timing accuracy ±0.5%

Frame deformation: ≤0.05mm

Maximum height of sample: 230mm

Throat: 165mm

Test force application method: automatic (loading/staying/unloading)

Hardness value display mode: touch screen display

Data output: Bluetooth printing

Power supply: 110V- 220V 50/60Hz

Dimensions: 520 x 215 x 700mm

Weight: N.W 60KG, G.W 82KG