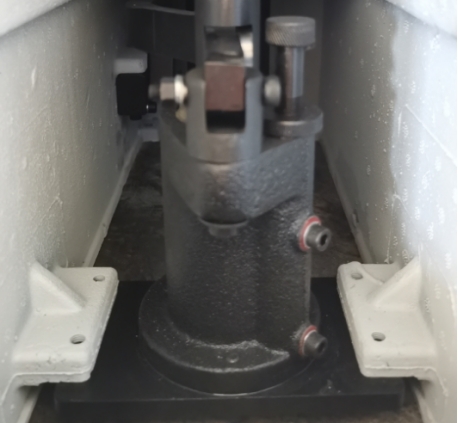

HR-45C Rockwell hardness tester

Suitable for surface quenching steel, material surface heat treatment and chemical treatment layer, copper, aluminum alloy, thin plate, galvanized, chromium plated, tin plated materials, bearing steel, chilled castings, etc.

Purely mechanical manual testing process, no electrical control required;

The machine has accurate data, reliable and durable products, and high testing efficiency; it is widely used for quality monitoring in production sites and has strong adaptability to the working environment;

Measuring range: 71-94HR15N, 42-86HR30N, 20-77HR45N

67-93HR15T, 29-82HR30T, 10-72HR45T

Initial test force: 3kgf (29.42N)

Total test force: 15kgf (147.1N), 30kgf (294.2N), 45kgf (441.3N)

Maximum height allowed for specimen: 175 mm

Distance from center of indenter to machine wall: 135mm

Indenter type: Rockwell diamond indenter

ф1.588mm steel ball indenter

Test force application method: manual

Hardness reading: dial reading

Hardness resolution: 0.5HR

Overall dimensions: 450*230*540mm; Packing size: 630x400x770mm

Weight: about 65KG, gross weight: 80KG

Main machine: 1 diamond cone indenter: 1

1/16" steel ball indenter: 1 large flat test bench: 1

Small flat test bench: 1 V-shaped test bench: 1

70~85 HR30T hardness block: 1pc 80~90 HR15N hardness block: 1 pc

65~80 HR30N hardness block: 1 pc