HR-150CS Rockwell hardness tester

Determine the Rockwell hardness of ferrous metals, non-ferrous metals, and non-metallic materials; wide range of applications, suitable for quenching

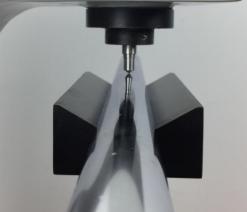

Rockwell hardness measurement for heat treatment such as quenching and tempering; curved surface measurement is stable and reliable.

Dial gauge directly reads hardness value of HRA, HRB and HRC scales; Friction-free spindle ensures test force accuracy;

Precision hydraulic buffer ensures smooth loading and unloading;

Independent suspended weights and core spindle system make the hardness value more accurate and stable;

Pure mechanical structure, no circuit part required, economical and practical

Measuring range: 20-95HRA,10-100HRB, 20-70HRC

Initial test force: 10kgf (98.7N)

Total test force: 588.4N, 980.7N, 1471N (60, 100, 150kgf)

Measuring scale: HRA, HRB, HRC scales can be read directly on the dial

Optional scales: HRD, HRF, HRG, HRH, HRE, HRK, HRL, HRM, HRP, HRR, HRS, HRV

Maximum height of specimen allowed: 175 mm

Distance from center of indenter to machine wall: 135 mm

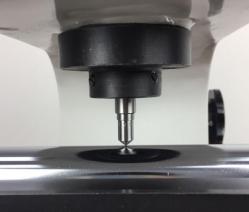

Indenter type: Rockwell diamond indenter, ф 1.588mm steel ball indenter

Test force application method: manual

Hardness reading: digitalreading

Hardness resolution: 0.1HR

Overall dimensions: 450*230*540mm

Packing size: 630x400x770mm

Weight: 80KG

| Main machine: 1 | 120° diamond indenter: 1 |

| Φ1.588 steel ball indenter: 1 | Large flat working table: 1 |

| Small flat workbench: 1 | V-shaped workbench: 1 |

| Rockwell hardness block: 60-70HRC | Rockwell hardness block: 80-100HRB |

| Rockwell hardness block: 20-30HRC | User manual: 1 copy |

| Screwdriver: 1 | Certificate 1 copy |