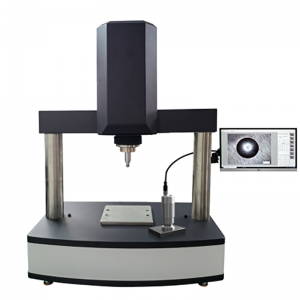

HBRVT-187.5 Computerised Digital Universal Hardness Tester

*HBRVS-187.5T Digital Brinell Rockwell & Vickers hardness tester is equipped with a newly-designed large displaying screen with good reliability, excellent operation and easy watching, thus it is a high-tech product combining the optic, mechanic and electric features.

*It has Brinell, Rockwell and Vickers three test modes and 7 level of test forces, which can test several kinds of hardness.

*Test force loading, dwell, unload adopts automatic shifting for easy and fast operation.

*It can show and set the present scale, test force, test indenter, dwell time and hardness conversion;

*The main function is as follows: Selection of Brinell, Rockwell and Vickers three test modes; Conversion scales of different kinds of hardness; Test results can be saved for checking or be printed out, automatic calculation of maximum, minimum and average value; With RS232 interface for connecting to the computer.

Suitable for hardened and surface hardened steel, hard alloy steel, casting parts, non-ferrous metals, various kinds of hardening and tempering steel and tempered steel, carburized steel sheet, soft metals, surface heat treating and chemical treating materials etc.

Rockwell Test Force: 60kgf (588.4N), 100kgf (980.7N), 150kgf (1471N)

Brinell Test Force: 30kgf (294.2N), 31.25kgf (306.5N), 62.5kgf (612.9N), 100kgf (980.7N), 187.5kgf (1839N)

Vickers Test Force: 30kgf (294.2N), 100kgf (980.7N) Indenter:

Diamond Rockwell Indenter, Diamond Vickers Indenter,

ф1.588mm, ф2.5mm, ф5mm Ball Indenter Hardness Reading:Touch Screen Display

Test Scale:HRA, HRB, HRC, HRD, HBW1/30, HBW2.5/31.25, HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5, HBW10/100, HV30, HV100

Conversion Scale:HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T,

Magnification:Brinell: 37.5×, Vickers: 75×

Min. Measuring Unit:Brinell: 0.5μm, Vickers: 0.25μm

Hardness Resolution:Rockwell: 0.1HR, Brinell: 0.1HBW, Vickers: 0.1HV

Dwell Time:0~60s

Max. Height of Specimen:

Rockwell: 230mm, Brinell: 150mm, Vickers: 165mm,

Throat:165mm

Data Output:Built-in Printer,RS232 Interface

Power Supply: AC220V,50Hz

Execute Standard:

ISO 6508,ASTM E18,JIS Z2245,GB/T 230.2 ISO 6506,ASTM E10,JIS Z2243,GB/T 231.2 ISO 6507,ASTM E92,JIS Z2244,GB/T 4340.2

Dimension: 475×200×700mm,

Net Weight: 70kg,Gross Weight: 90kg

| Name | Qty | Name |

Qty |

| Instrument Main Body |

1 set |

Diamond Rockwell Indenter |

1 pc |

| Diamond Vickers Indenter | 1 pc | ф1.588mm, ф2.5mm, ф5mm Ball Indenter |

each 1 pc |

| Slipped Test Table | 1 pc | Middle Plane Test Table |

1 pc |

| Large Plane Test Table | 1 pc | V-shaped Test Table |

1 pc |

| 15× Digital Measuring Eyepiece | 1 pc | 2.5×, 5× Objective |

each 1 pc |

| Microscope System (include the inside light and outside light) |

1 set |

Hardness Block 150~250 HB W 2.5/187.5 |

1 pc |

| Hardness Block 60~70 HRC | 1 pc | Hardness Block 20~30 HRC |

1 pc |

| Hardness Block 80~100 HRB | 1 pc | Hardness Block 700~800 HV 30 |

1 pc |

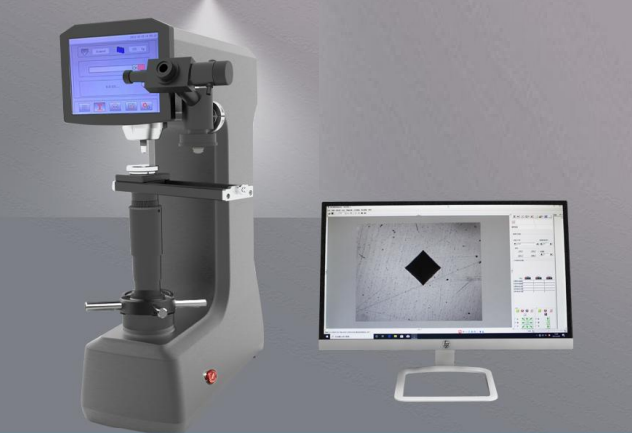

| CCD imaging measuring system | 1 set | Power Cable | 1 pc |

| Usage Instruction Manual | 1 copy | Computer(Optional) | 1 pc |

| Certification | 1 copy | Anti-dust Cover | 1 pc |

Vickers:

* The CCD image processing system can finish the process automatically: measurement of the diagonal length of indentation, hardness value display, testing data and image saving, etc.

* It is available to preset the upper and lower limit of hardness value, the testing result can be inspected whether it is qualified automatically.

* Proceed hardness testing on 20 test points at one time (preset the distance between test points at will), and save the testing results as one group.

* Converting between various hardness scales and tensile strength

* Inquire the saved data and image at any time

* Customer may adjust the accuracy of the measured hardness value at any time according to the calibration of Hardness Tester

* The measured HV value can be converted to other hardness scales(HB,HRetc)

* System provides a rich set of image procsessing tools for advanced users.the standard tools in the system include adjusting Brightness,Contrast,Gamma,and Histogram Level,and the Sharpen,Smooth,Invert,and Convert to Grey functions.On grey scale images,system provides various advanced tools in filtering and finding edges,as well as some standard tools in morphological operations such as Open,Close,Dilation,Erosion,Skeletonize,and Flood Fill etc

* System provides the tools to draw and measure common geometric shaps such sa lines,angles 4-point angles (for missing or hidden vertexes),ractangles ,circles,ellipses,and polygons.Note that the measurement assumes the system is calibrated.

* System allows user manage multiple images in an album which can be saved to and opened from an album file.the images can have the standard geometric shapes and the documents as entered by user as described above

On an image,system provides a document editor to enter/edit documents with contents either in simple plain test format or in advanced HTML format with objects including tabes,list,and images.

*System can print the image with user specified magnification if it is calibrated.

It can be used to determine the Vickers hardness of steel, non-ferrous metals, ceramics, treated layers of metal surface, and the hardness grads of carburized, nitrided and hardened layers of metals. It is also suitable to determine the Vickers hardness of micro and super thin parts.

Brinell:

1. Automatic measurement: Automatically capture the indentation and measure the diameter and calculate the corresponding value of Brinell hardness;

2. Manual measurement: Manually measure the indentation, the system calculates the corresponding value of Brinell hardness;

3. Hardness conversion: The system can convert the measured Brinell hardness value HB to other hardness value such as HV, HR etc;

4. Data statistics: The system can automatically calculate the average value, variance and other statistical value of the hardness;

5. Standard exceeding alarm: Automatic mark the abnormal value, when the hardness exceeds the specified value, it automatically alarms;

6. Test report: Automatically generate the report of WORD format, the report templates can be modified by the user.

7. Data storage: Measurement data including the indentation image can be stored into file.

8. Other function: include all functions of image processing and measurement system, such as image capture, calibration, image processing, geometric measurement, annotation, photo album management and fixed times print etc.