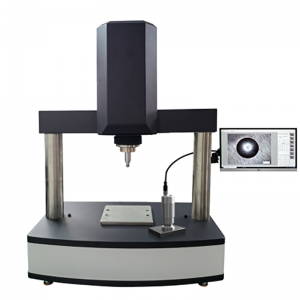

HB-3000MS Automatic Measuring Briness Hardness Tester

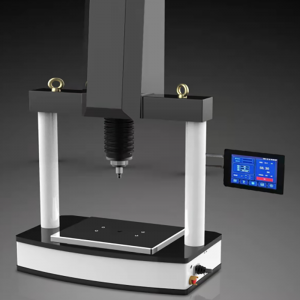

The portal frame structure can test the hardness of large workpieces (customized).

Using a dedicated numerical control system, a closed-loop electronic control system exerts the test force. The transmission part of the whole machine is completely composed of a stepping motor and a ball screw.

The failure rate of the whole machine is low, maintenance is time-saving and labor-saving, and no hydraulic oil is required.It is stable and reliable when used in environments with large temperature differences.

Application: It is suitable for the hardness test of cast iron, steel, non-ferrous metals and soft alloys, and also for the hardness test of some non-metallic materials such as hard plastics and bakelite.

Loading mechanism: Fully closed-loop control sensor loading technology is adopted, without any load impact error, monitoring frequency is 100HZ, and the internal control accuracy of the whole process reaches 0.5%; the loading system is directly connected to the load sensor without any intermediate structure, and the load sensor directly measures the load of the monitoring pressure head for adjusting, the coaxial loading technology, no lever structure, not affected by friction and other factors; the unconventional closed-loop control system of the lead screw lifting loading system, the double linear frictionless bearing executes the probe stroke, almost no need to consider the aging and errors caused by any screw system;

Electrical control mechanism: high-end electrical control box, well-known brand electrical components, servo control system etc.

Safety protection device: all strokes adopt limit switches to ensure the operation of the equipment in the safe interval; except for the necessary exposed components, the rest adopts a covered structure.

Operation and display: computer touch screen control, ergonomic design, beautiful and practical.

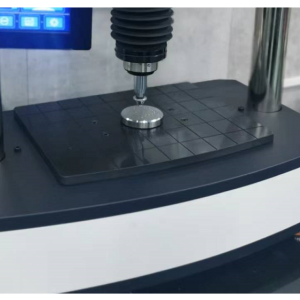

Indentation measurement & reading: Fully automatic Brinell hardness measurement system.

Control system: touch screen control

Measuring:4-650HBW

Test force:62.5,187.5, 250, 500,750,1000,1500,3000kgf

Indentation measurement method: computer automatic measurement (or manual measurement)

Conversion ruler:HV, HK, HRA, HRBW, HRC, HRD, HREW, HRFW, HRGW, HRKW, HR15N, HR30N, HR45N, HR15TW, HR30TW, HR45TW, HS, HBS, HBW

Motor type:servo motor

Transmission mode: ball screw

Loading time: 1-99 seconds adjustable

The distance between the two columns: 570mm (can be customized on demand)

The maximum height of the workpiece : 230mm (can be customized on demand)

Moving distance of worktable: 100mm (optional)

size:main machine 750*450*1100mm

Power:220V,50/60Hz

Net weight:about 300kg

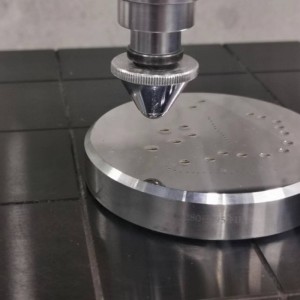

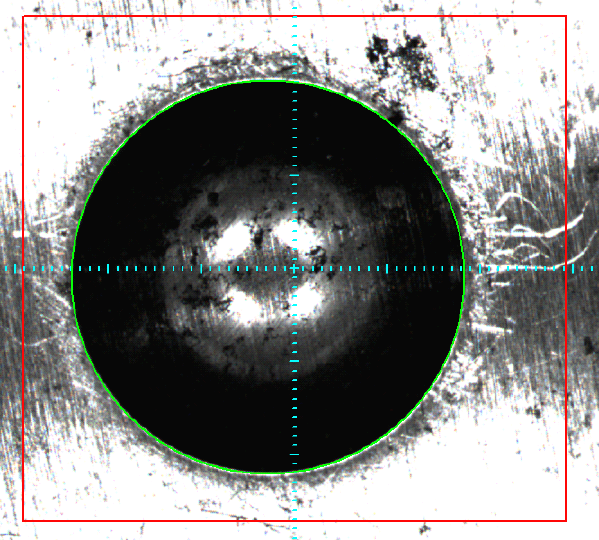

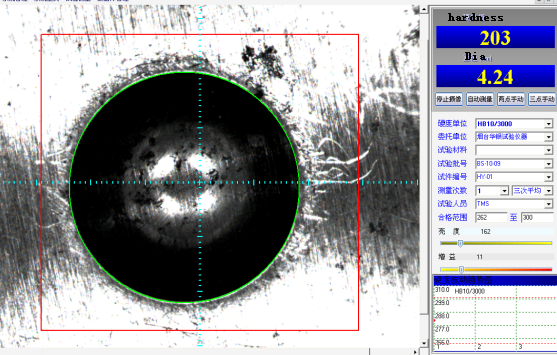

This system has both manual and fully automatic measurement functions. Makes the operation very simple and reliable. As shown below:

As long as the indentation appears in the screen area without any operation, the indentation diameter and hardness value will be displayed on the upper right.

Using large-screen flat LCD touch screen. Simply click with the mouse to select the program; the interface is clear and there is no visual error, it can display the holding time of the indentation image, the test force, the objective lens, the indenter selection, the distance measurement, the hardness value conversion, and the report output data.

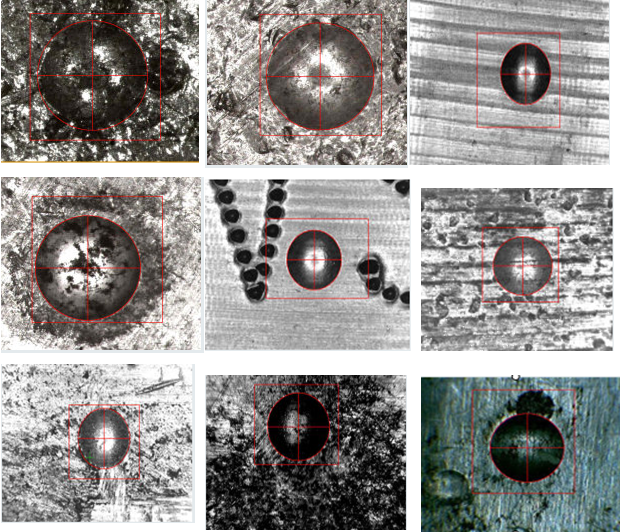

The system can accurately distinguish Brinell indentation images in complex backgrounds. The following pictures are measurement images of various complex backgrounds.

Double column Brinell hardness tester 1 set

Φ2.5, Φ5mm, Φ10mm, 1 each

A set of automatic measurement system (including computer, CCD image sensor, dongle, software, data cable)

2pcs Brinell hardness standard blocks